Everything about bundle wrappers

If you’re searching for a cost-effective way and aesthetic look to wrap your products, Bundle Wrappers, also known as Sleeve Wrappers, offer a brilliant solution.

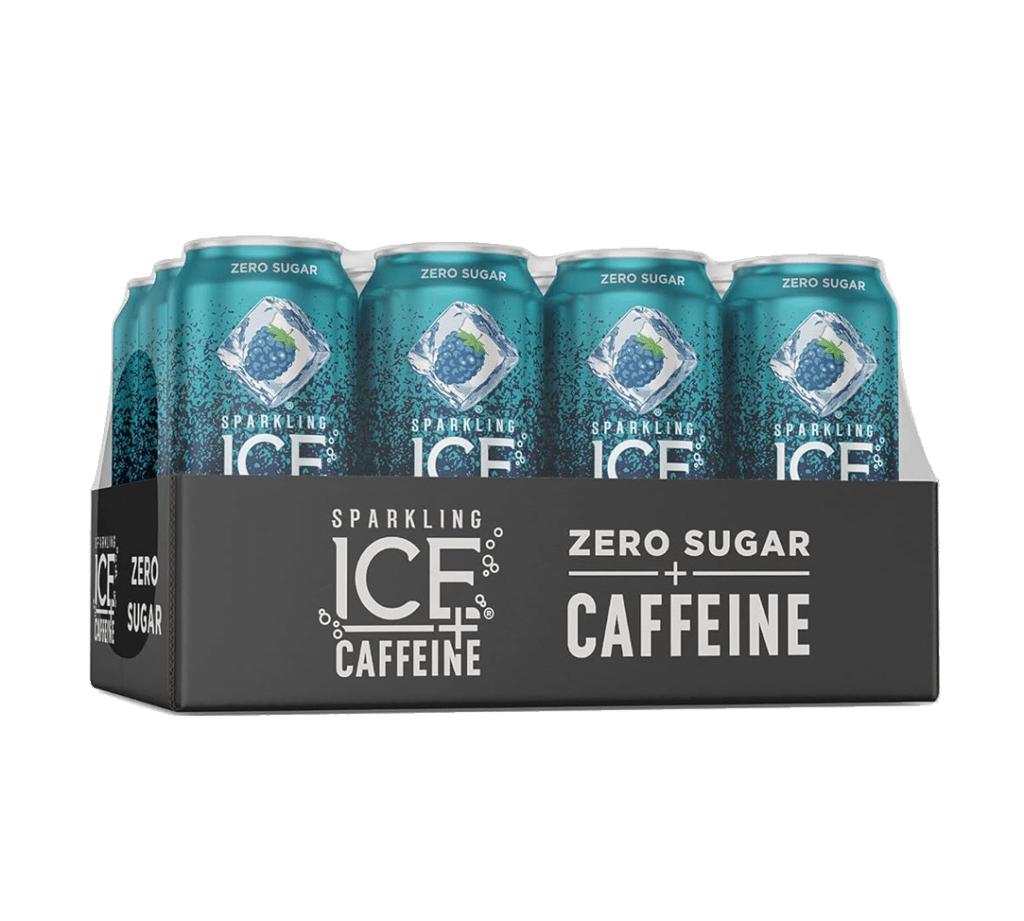

These machines are designed to bundle products together, such as bottles, cans, and boxes, and then apply a protective sleeve or film around them. They are commonly used in industries such as food and beverage, pharmaceuticals, and logistics to enhance the efficiency of packaging processes.

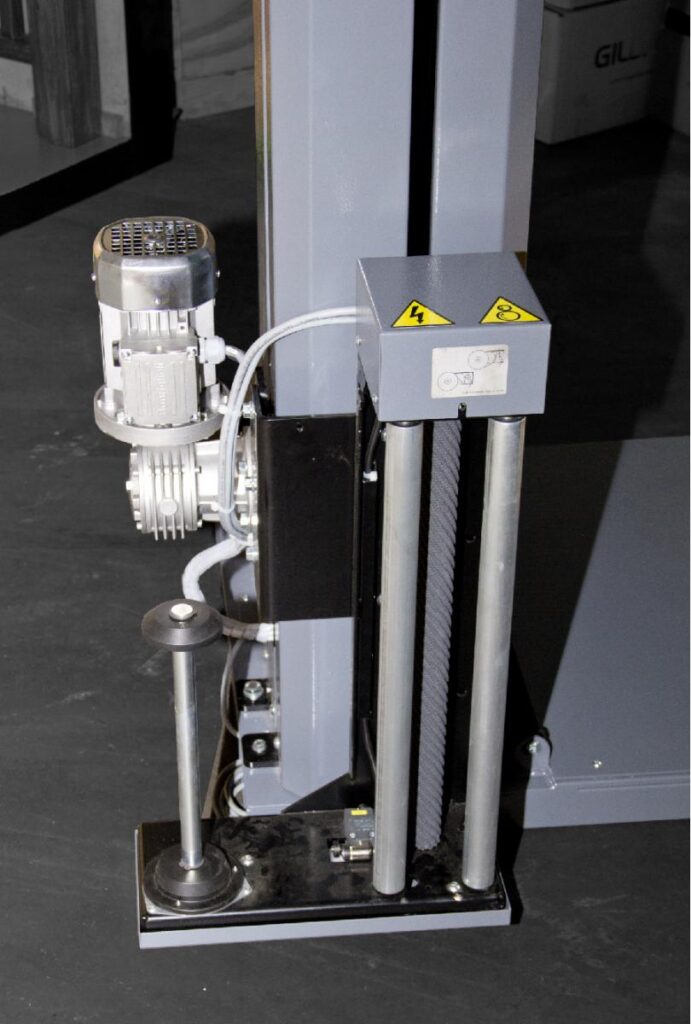

How Do Bundle Wrappers Work?

ways to wrap with bundle wrappers

Bundle wrappers offer versatility in achieving various packaging aesthetics based on your preferences. Before investing in a bundle wrapper, it’s essential to consider three primary packaging options and which one you prefer the most.

Shrink Wrapping with Tray

Bundle wrappers can wrap either the bundle on the tray or the bundle by itself.

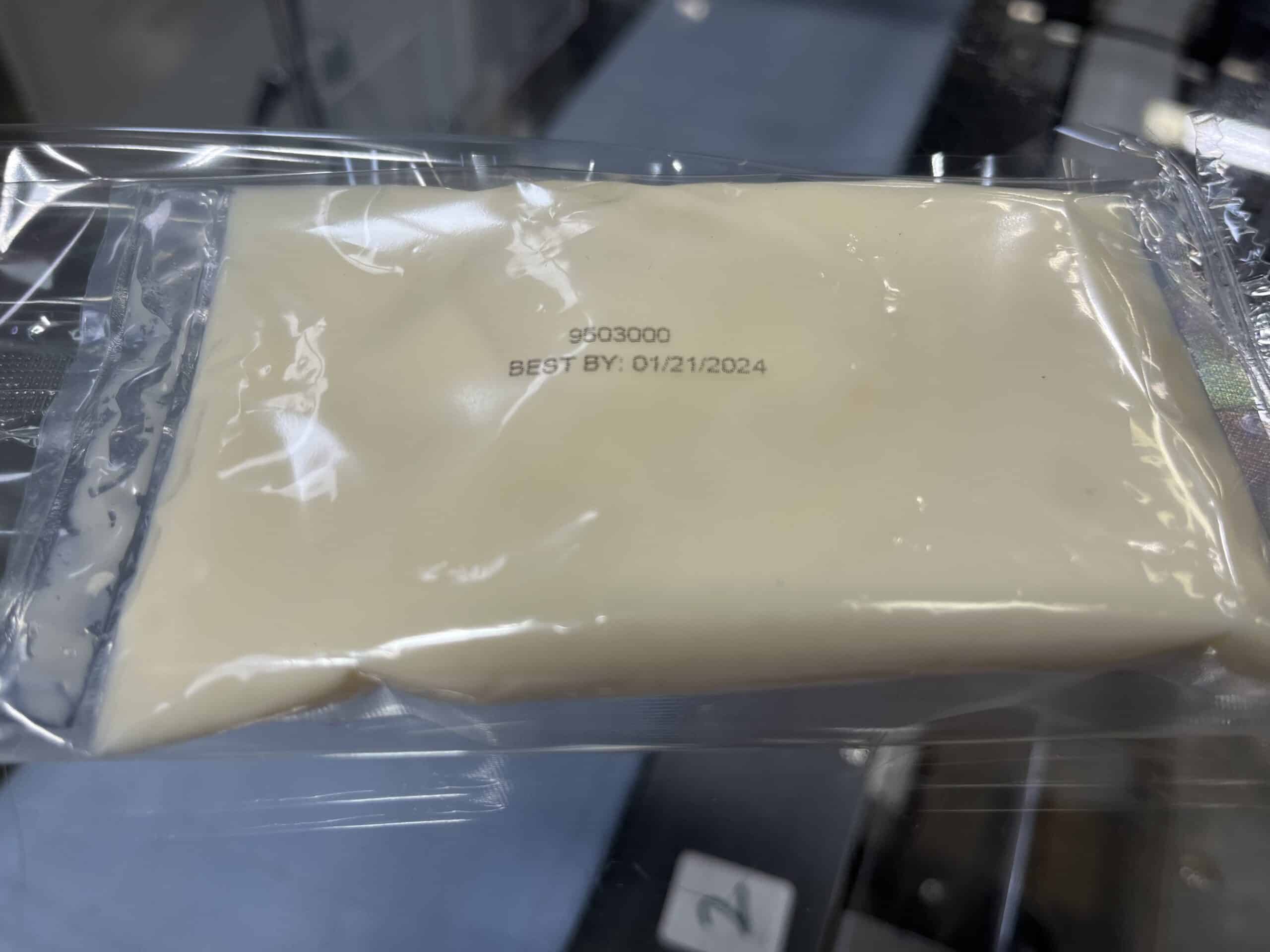

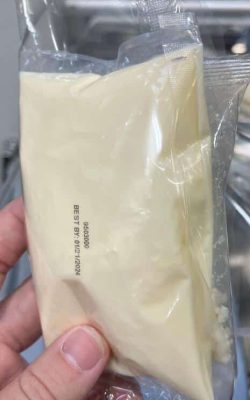

Shrink Wrapping Without Tray

The machine can create bullet holes on the side for easier gripping of the bundle, or it can provide a full closure without any holes.

With Printed or Regular Film

Benefits of Bundle Wrappers

Bundle wrappers recommendations

SMI XP650

best

An automatic overlap wrapper designed for high-speed shrink sleeving/bundle wrapping with printed film registration capabilities

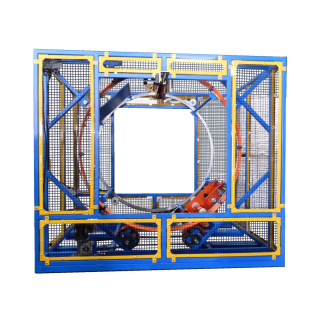

IMPAK MB3216

A reasonable manual shrink sleeving/bundle wrapping machine

No Compressed Air Required

Tunnel Opening: 32” W x 16” H.

All-in-One System – Wraps and Shrinks

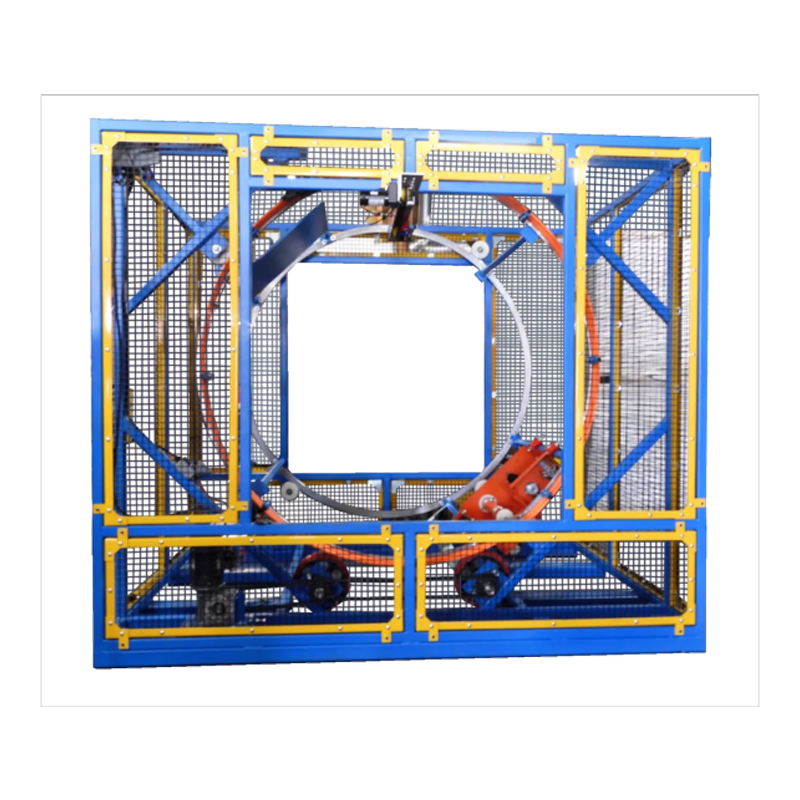

SMI BP800AS

A versatile automatic shrink sleeving/bundle wrapping machine

Suitable for packing glass and PET bottles, cans, boxes, trays, jars, and cartons of various sizes in different pack collations.

Used in industries like beverages, food, chemicals, wine and spirits, cosmetics, detergents, wood, textile, and graphics

The AS Model includes an optional Infeed Conveyor System and pushdown wipers.

SMI XP650

A high-speed automatic overlap shrink sleeving/bundle wrapper

Suitable for the food industry and complies with FDA, UE, and USDA standards for products in direct contact with food.

Features a stainless-steel frame and FDA-compliant conveyor.

Capable of registering print

get a bundle wrapper consultation today!

Key Features to Consider

1. Film Type

Consider how thick the Shrink film should be and width of it. The poly shrink film is used for bundle wrappers. Various thickness options are available, ranging from 1 mil to 4 mil, allowing you to choose the desired thickness for your needs. You can select a thickness depending on the weight of the bundle you want to wrap. The most common shrink film is 2.5 mil which is the LCBO requirement for tall can cases.

The width of the shrink film should be chosen to adequately cover the entire bundle. Measure the dimensions of your bundle and ensure the film’s width can comfortably accommodate it.

2. Speed and Capacity

Think about how many bundles you intend to produce in an hour. Understanding your desired production rate will help you select a machine that can meet your output goals efficiently. Determine how many products will be packed in one bundle and the weight of the bundle. It is crucial in assessing the machine’s capability to handle the necessary volume.

3. Automation Level

Evaluate the level of automation you need, ranging from manual to fully automatic Bundle Wrappers. The choice of automation level should align with your production volume, the level of operator involvement you prefer, and the overall efficiency you aim to achieve in your packaging process.

4. Space and Energy Efficiency

Determine the available space in your facility and choose a machine that fits seamlessly. Additionally, opt for energy-efficient models to reduce operational costs.

FAQ

Most Frequent Questions and Answers

Yes, most Bundle Wrappers are designed for seamless integration into existing production lines, improving overall efficiency.

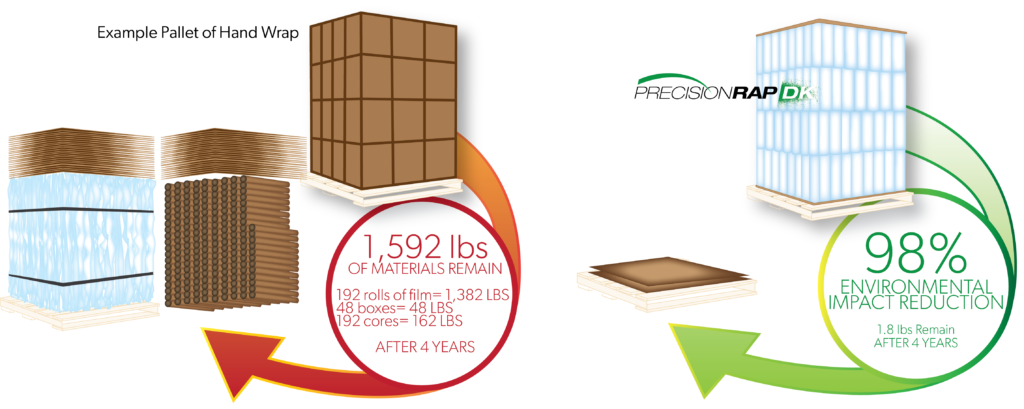

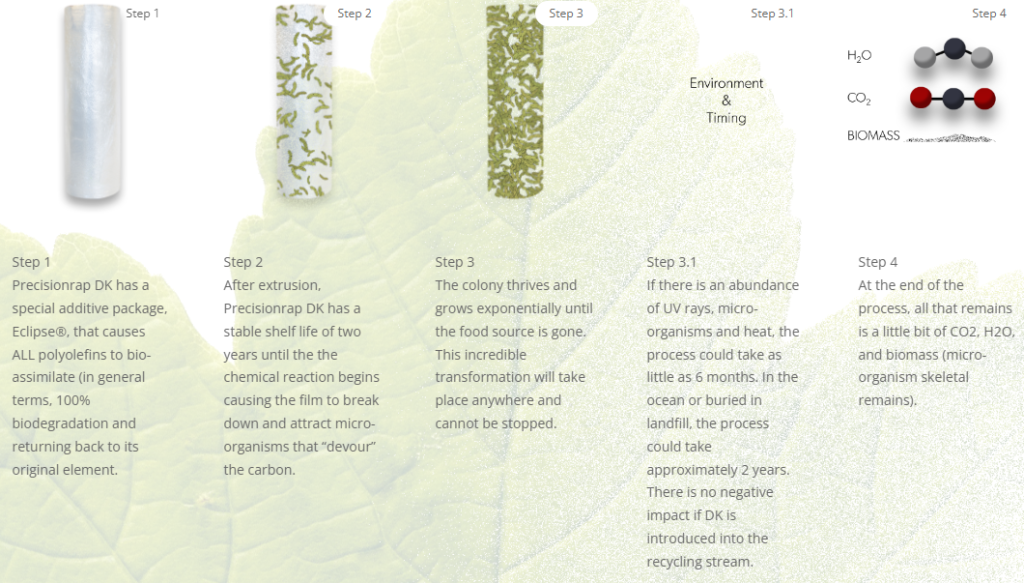

Yes, there are biodegradable and recyclable shrink films available that can be used with Bundle Wrappers, promoting environmentally friendly packaging practices.

Absolutely, Bundle Wrappers can be adjusted to handle delicate products with care, ensuring they remain intact during packaging.

Yes, there are fully automatic Bundle Wrappers designed for high-speed and high-volume production to meet the demands of various industries.

Have a question about equipment or service?

Just give us a call or send us a message with the form below. One of our customer service representatives would be happy to help you with whatever you need.

400 Flint Rd.

North York, Ontario

M3J 2J4

Phone: 416-299-0960

Fax: 416-299-0961

Email: [email protected]