What is a Biodegradable Stretch Film?

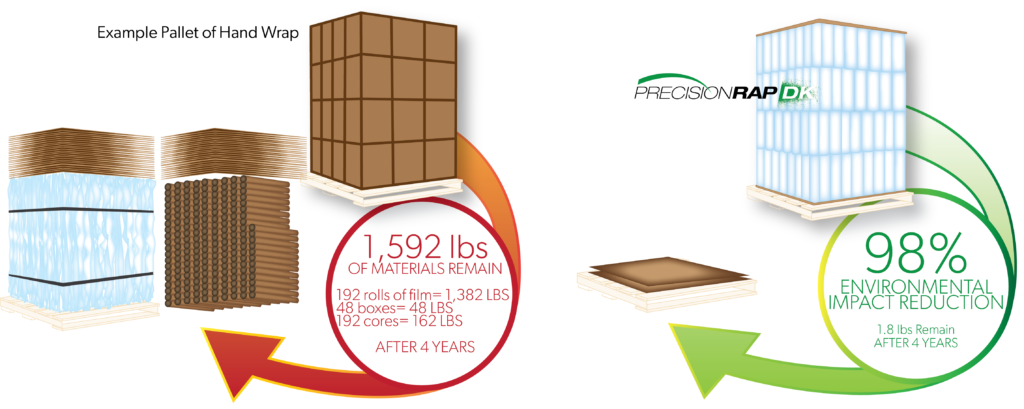

Traditional plastic stretch films, although recyclable, often end up in landfills. This concern has spurred the development of biodegradable stretch films like Precisionrap DK.

If your business is trying to become more sustainable, the chances are you’ll have discussed how you can make your packaging fit in with this. Among various packaging solutions, biodegradable stretch films have emerged as a promising solution to address environmental concerns associated with conventional plastics. This article delves into Precisionrap DK stretch wrap, a biodegradable alternative that offers both performance and eco-consciousness.

Precisionrap DK Stretch Wrap: A greener choice

Precisionrap DK stretch wrap is a cutting-edge packaging solution designed to cater to the needs of both businesses and the environment. It shares many characteristics with traditional stretch films, such as excellent load stability, protection against moisture and dust, and ease of application. For example, the total film stretches of 285% with a hand application.

However, its key differentiator lies in its biodegradability. It takes a few years to decay, not decades. This can help company’s sustainability goals without a hassle of recycling, while the pricing is same as other Precision product.

Benefits of Precisionrap DK Stretch Wrap

Precisionrap : cost-effective and efficient solution

Precisionrap has a two-part handheld dispenser, which allows ergonomic stretch wrap usage. Aside from less intensity of labour, Precisionrap also offers several key advantages over traditional hand pallet wrapping techniques:

Film Efficiency: Precisionrap consumes less film by weight compared to traditional methods. Based on a cut and weigh test by rewrapping a pallet with Precisionrap and comparing film weights, customers can reduce their film consumption by a minimum of 35%.

Improved Load Containment: According to the force-to-load measurement, Precisionrap significantly enhances load containment, exerting up to 50% more force on the load to maintain its integrity compared to traditional hand-wrapping techniques.

Faster Wrapping: With Precisionrap, you can wrap a typical load 33% faster than with manual hand wrapping. Precisionrap streamlines the process without compromising on wrapping quality.

Consistent Containment: Precisionrap ensures consistency and containment with its snapback test. This test measures the film’s ability to recover to its pre-applied length after being cut vertically. Precisionrap consistently achieves greater and more consistent snapback and load containment compared to traditional hand-wrapped pallets, regardless of the operator.

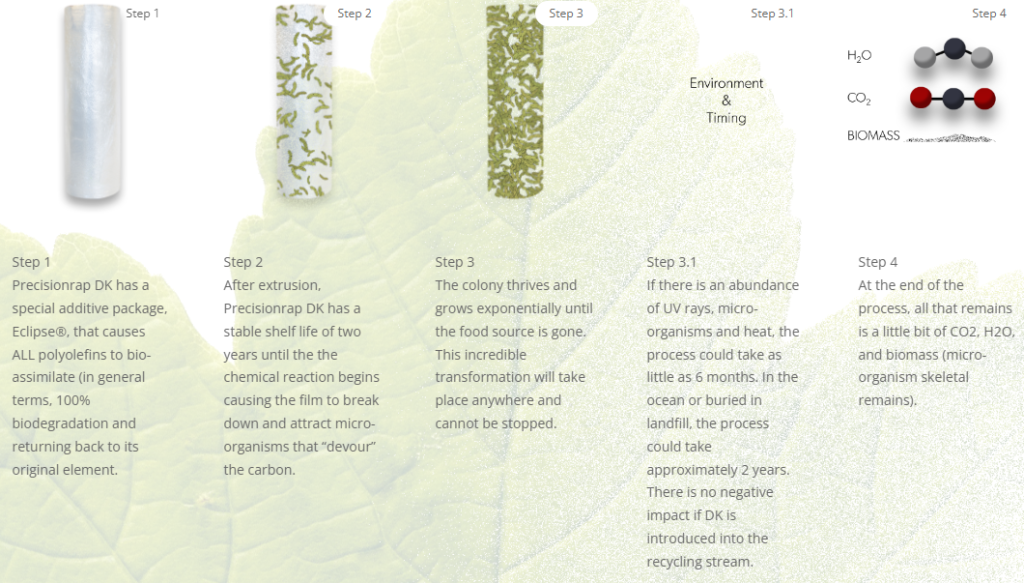

Biodegrading process of Stretch Films

Get a greener Stretch wrap quote Today!

Have a question about equipment or service?

Just give us a call or send us a message with the form below. One of our customer service representatives would be happy to help you with whatever you need.

400 Flint Rd.

North York, Ontario

M3J 2J4

Phone: 416-299-0960

Fax: 416-299-0961

Email: [email protected]