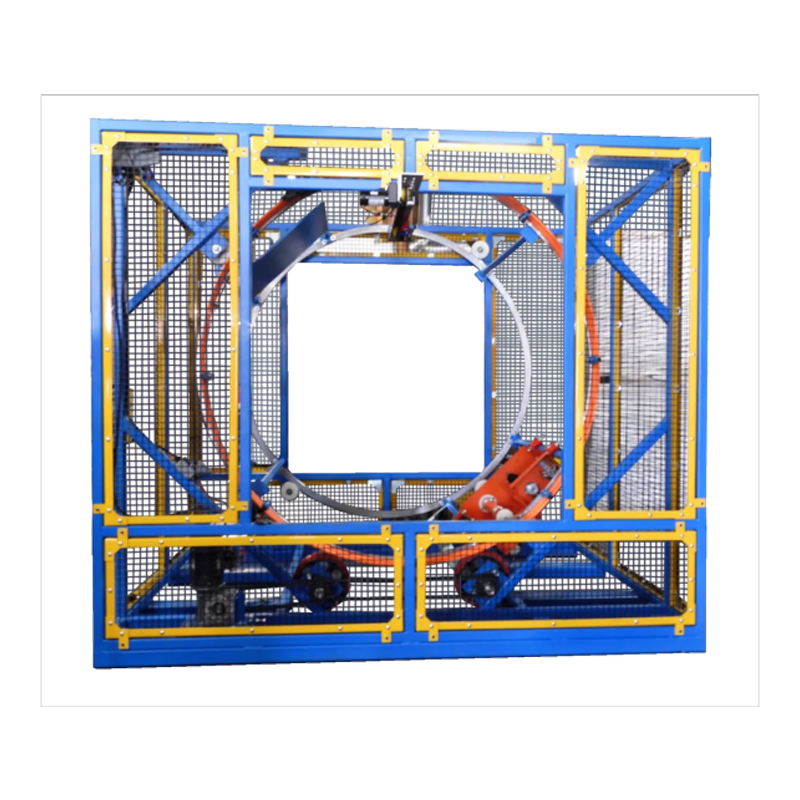

Stretch Wrapper Preventative Maintenance

If you just purchased a stretch wrapper or it has been 10 years of using it, nothing is more frustrating than breakdown of the machine. The breakdown results in costly downtime and additional cost of servicing fee for a technician to investigate and fix the issue. To prevent unexpected problems to occur, you should take some time to maintain your machine. Now you might say, how? I am not a machine engineer. Don’t worry, with a little bit of attention, you might save yourself from machine breakdown. Let’s dive into the step-by-step process to keep the stretch wrapper running smoothly.

Step-by-Step Process for Maintenance Day

Creating a regular maintenance plan is the first step toward ensuring the longevity and efficiency of your stretch wrapper. By proactively maintaining the machine, you can prevent costly downtime and expense. Let’s dive into the step-by-step breakdown of what your maintenance day should look like.

1. Preparation

Unplug the machine from the power outlet and clean out any debris from around and under the pallet wrapping machine. Over time, pieces of stretch film, chips of wood from pallets, and trash will be underneath the machine.

2. Visual Inspections

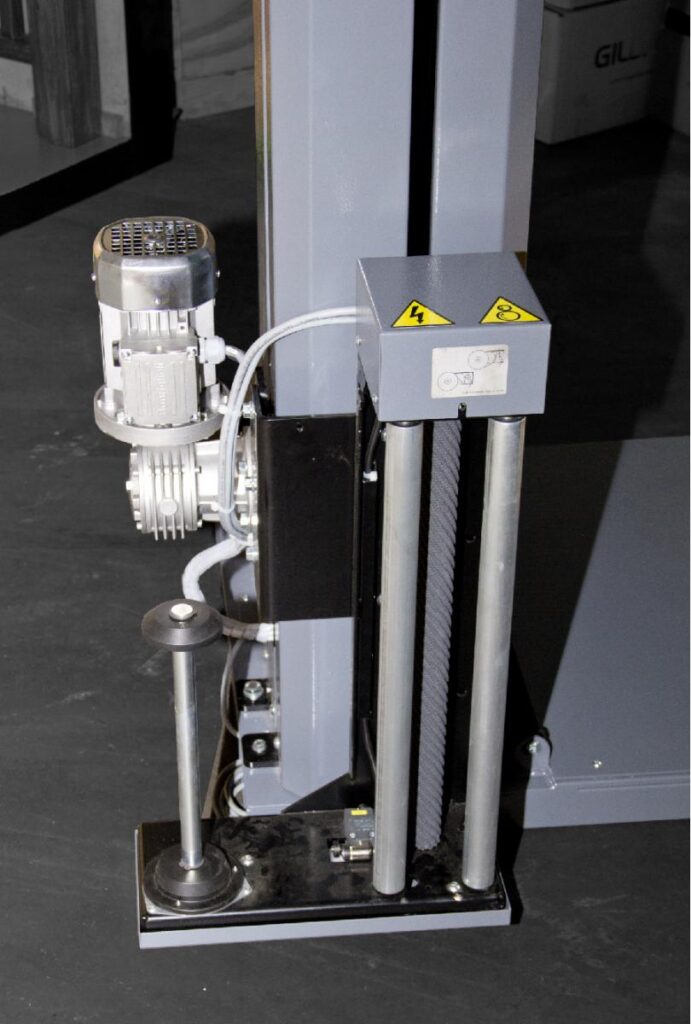

Start by conducting regular visual inspections. Examine all components of the stretch wrapper, including rollers, belts, and the turntable, for signs of wear and tear. Cracks, fraying, or loose parts can lead to issues, so replace any damaged components promptly to prevent breakdowns.

3. Cleaning

4. Lubrication

Proper lubrication of moving parts, including bearings, bushings is essential. This is because insufficient lubrication can lead to increased machine temperature and a higher energy demand for its operation. However, avoid over-lubricating as it can cause the grease to splatter and accumulate on other parts. To determine the right lubrication type and schedule, refer to your equipment’s manual.

5. Calibration

Ensure that your stretch wrapper is correctly calibrated to apply the right amount of tension to the stretch film based on the type and size of the load. Improper tension can result in product damage or inefficient wrapping. After all the process above, plug in the machine and perform a test wrap.

6. Documentation of Procedures

Maintain a detailed record of maintenance procedures and schedules. This documentation ensures that maintenance tasks are carried out consistently and enables quick troubleshooting when issues arise.

frequent asked Questions

How often should we maintain the stretch wrapper?

It’s recommended to perform routine maintenance every 3 to 6 months, depending on your usage. For some parts, it also depends on the model you purchased. Talk to your machine manufacturer or service provider for more detailed instruction.

Are there any indicators that my stretch wrapper needs maintenance?

Yes, signs like unusual noises, reduced wrapping quality, or visible wear and tear are indicators that maintenance is needed. But if the issue occurs even after the checkup, it’s best to consult a professional technician.

our preventative maintenance program

Common Issues and Trouble-shooting

Even with regular maintenance, issues may still arise. Here are some common problems and their solutions.

1. Wrinkled Film

If your stretch film appears wrinkled or loose, check the film tension settings and adjust accordingly.

2. Film Breaks

Film breaks can disrupt operations. Inspect the film roll for any defects and ensure it’s loaded correctly.

3. Unstable Loads

If your pallet loads are unstable, it could be due to inadequate film application. Reevaluate the wrapping patterns and settings.

Have a question about equipment or service?

Just give us a call or send us a message with the form below. One of our customer service representatives would be happy to help you with whatever you need.

400 Flint Rd.

North York, Ontario

M3J 2J4

Phone: 416-299-0960

Fax: 416-299-0961

Email: [email protected]