Largest Inventory of New & used Stretch Wrappers / pallet wrappers in Canada!

From now until September 30th, 2024 June 30th, 2025 save up to $1500 on your first skid of stretch wrap when you buy a new stretch wrapper from Gertex Solutions or Impak Packaging.

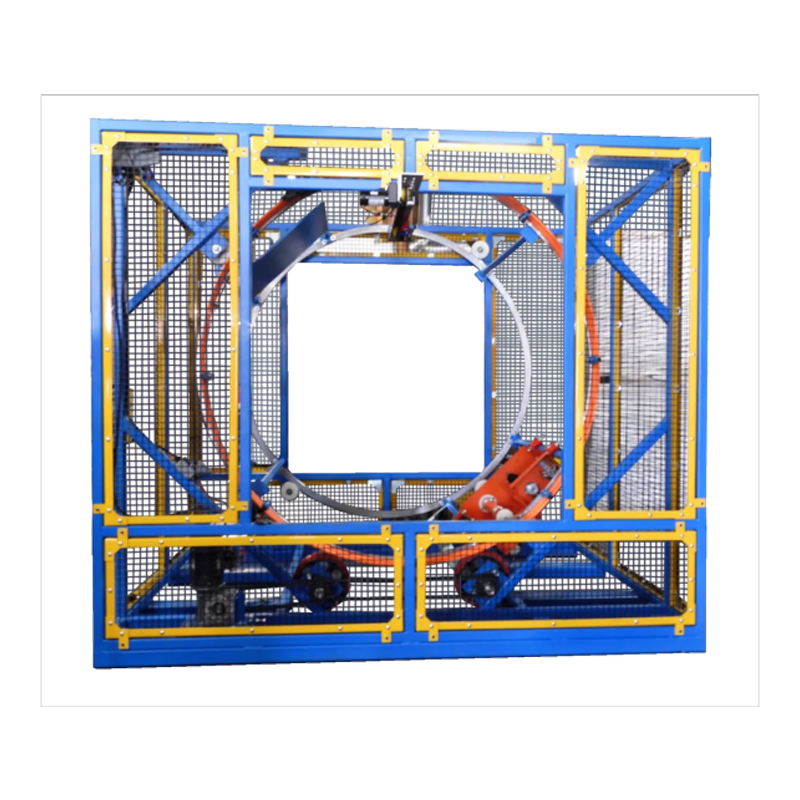

We hold the largest inventory of new & refurbished packaging equipment in Canada. We inventory turntable stretch wrappers, rotary arm stretch wrappers, and ring / rotary arm stretch wrappers. Our large inventories allow for reduced lead times, parts for all stretch wrappers, superior service, and the lowest prices. We source the highest quality pallet wrapper parts for a variety of brands so that you have exactly what you need, right when you need it. Our technicians have on average 20 years working on packaging equipment. This allows us for quick turn-around service on new, and refurbished equipment, as well as to resolve Stretch Wrapper issues without the headache.

STRETCH WRAPPERS FROM THE BEST BRANDs

Our diverse range of pallet wrapper suppliers ensures we are there to help when you need us. We’ve had decades long relationships with these brands, and have reduced lead times, competitive pricing and a service team that knows the machines. With our Plug & Play set-up, these machines are ready to go as soon as they land on your floor. These stretch wrapper providers are the best in the industry, and are tried, and tested. Click here for our Full Line-Up of Stretch Wrap Machines.

NEW PALLET WRAPPERS AVAILABLE TO BUY, RENT OR LEASE

Save up to $1500 on your first skid of stretch wrap when you buy a new stretch wrapper from Gertex Solutions or Impak Packaging.

Impak Packaging is a leading Canadian supplier of stretch wrapper / pallet wrapping machines and equipment. We house a large inventory of pallet wrapper machines from manual, to fully automatic, from the best brands in North America. We are equipped to provide packaging solutions to meet every customer’s needs, coast to coast and throughout North America. We keep our customers ahead of their competition by supplying them with the very best technical support, pricing and application knowledge to drive down costs and increase productivity.

Frequently Asked Questions about Pallet Wrappers

Hand-Wrapping is often sufficient for small-scale operations, but as your business grows, inefficiencies in hand-wrapping can lead to higher costs, inconsistent wrap quality, and employee fatigue. If you’re wrapping more than 10-15 pallets a day, or noticing damage during transit due to uneven wrapping, it’s time to consider upgrading to a Pallet Wrapper. The machine ensures consistent, secure wrapping while saving time and reducing material waste.

A Pre-Stretch Carriage stretches the Stretch Film before it’s applied to the pallet, optimizing the use of film by up to 250-300%. This not only reduces material costs but also provides a tighter and more secure wrap, improving load stability during transit. It’s an essential feature for businesses looking to save money and enhance packaging efficiency.

Not at all! Most pallet-wrapping machines are user-friendly and come with intuitive controls. Many models offer programmable settings for different load types, so operators can achieve optimal wrapping with minimal training.

Pallet wrappers are versatile and can handle a wide range of loads, from lightweight and irregularly shaped products to heavy and uniform pallets. Adjustable tension settings ensure that even delicate items can be securely wrapped without damage.

The space needed depends on the type of pallet wrapper. Turntable models typically require less space, while rotary arm models may need more clearance. Most manufacturers provide detailed specifications to help you plan your workspace accordingly.

Consistent and secure wrapping minimizes the risk of load shifting or damage during transit, reducing claims and improving customer satisfaction. Automated wrapping also speeds up the packaging process, ensuring timely shipments.

Yes, like any equipment, pallet wrappers benefit from regular maintenance to ensure optimal performance. This includes cleaning, checking for wear on moving parts, and replacing the stretch film carriage rollers periodically.

case studies

Looking for a Packaging Audit?

Just give us a call or send us a message with the form below. One of our customer service representatives would be happy to help you with whatever you need.

110A Iron St.

Etobicoke, Ontario

M9W 5L9

Phone: 416-299-0960

Fax: 416-299-0961

Email: info@impakpackaging.com