Stretch wrapping basics

Stretch wrapping is a technique used throughout the packaging industry to secure products to a skid and provide extra protection while in transport. This technique is particularly useful while shipping several boxes or products on a skid. Pallet Wrapping will ensure that your products are safe, stabilized and secure so they reach your customer without being damaged or tampered. This article aims to give you a clear understanding of how stretch wrapping works and how it is implemented. You need to follow certain steps so that you stretch wrap your products properly preventing them from getting damaged during the shipping process.

stretch film

Stretch Film

Stretch Wrapping Equipment

Different types of pallet wrappers

The Turntable Pallet Wrapper is like a spinning plate for pallets. Just like the name sounds, this machine has a turntable on the bottom of the structure that spins. You place the pallet on the rotating platform, and a roll of stretch film is dispended high to low as it turns. You can adjust the tightness and number of wraps as needed. It’s an easy and effective way to protect and contain products during transport.

Imagine a big oscillating arm that hugs your pallet with stretch film to ensure containment during transport – that’s the Rotary Arm Pallet Wrapper. The pallet stays still, and the arm moves around the skid, wrapping the film from top to bottom. This method is great for fast and stable wrapping, especially for tricky loads that may wobble.

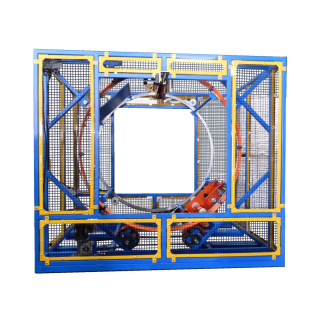

The Orbital Pallet Wrapper is perfect for irregularly shaped loads. Instead of spinning the pallet, it wraps the film around the load horizontally from all sides. This ensures that every part of the load is securely covered, preventing any shifting during shipping. This type of stretch wrapping machine is perfect for long product like furniture and cabinetry.

The Mobile Pallet Wrapper is like a compact wrapping machine on wheels. You can take it anywhere in your warehouse, no fixed spot needed. Just place the pallet on the floor, attach the film, and let the machine move around the pallet to wrap it up neatly. It’s convenient, safe and saves time!

Key Considerations FOR hand WRAPPING

The following are the steps to be considered before stretch wrapping a skid using a hand film:

1. Select the right size pallet or skid

Make sure you stack your boxes or products using the right size skid. Using a skid that is too large or too small will result in an insecure and unstable load. The best size is one that is not larger than the products placed on top otherwise the plastic may tear on the sharp pallet corners; yet the pallet has to completely cover the base area of the products you want wrapped or you may have damage to your products in shipping.

2. Stack the base of the skid properly

If you have different size boxes, make sure to place the larger heavier boxes on the pallet first. Make sure not to leave any gaps and occupy as much space as you can to make the base stable and secure.

3. Stack the rest of your boxes on the skid

Properly place the remaining boxes or products on the skid. Make sure that your boxes do not cross the edges of the pallet and placed them as close as possible to each other in order to prevent them from moving after being wrapped. Do not stack your pallet too high as it can destabilize the load by raising the center of gravity. Make sure your skid is in cubical or square shape.

4. Start the Stretch Wrapping Process

Tie the stretch film around the corner of the skid. This will ensure that the film does not come off while wrapping. While holding the hand stretch wrapper, start walking around the skid. Once you reach the corners of the skid, tightly secure and apply tension ensuring it is nice and tight around the load. Always start from the bottom and then go towards the top. It is recommended that you go around the skid at least 5-6 times to ensure stability. Once the wrapping is finished, check the skid thoroughly for sturdiness. If the load is moving and is not stable, you should consider wrapping it again. Once your pallet is stable and sturdy, tear the stretch wrap from the skid and you are done.

get a free consultation today!

If you have a high volume of skids or pallets to wrap, we recommend using a machine pallet wrapper. If you have any questions about stretch wrapping and wrapping equipment, please call us at (416) 299-0960 and a representative will guide you in selecting the right stretch film and equipment for your packaging needs.

Have a question about equipment or service?

Just give us a call or send us a message with the form below. One of our customer service representatives would be happy to help you with whatever you need.

400 Flint Rd.

North York, Ontario

M3J 2J4

Phone: 416-299-0960

Fax: 416-299-0961

Email: [email protected]