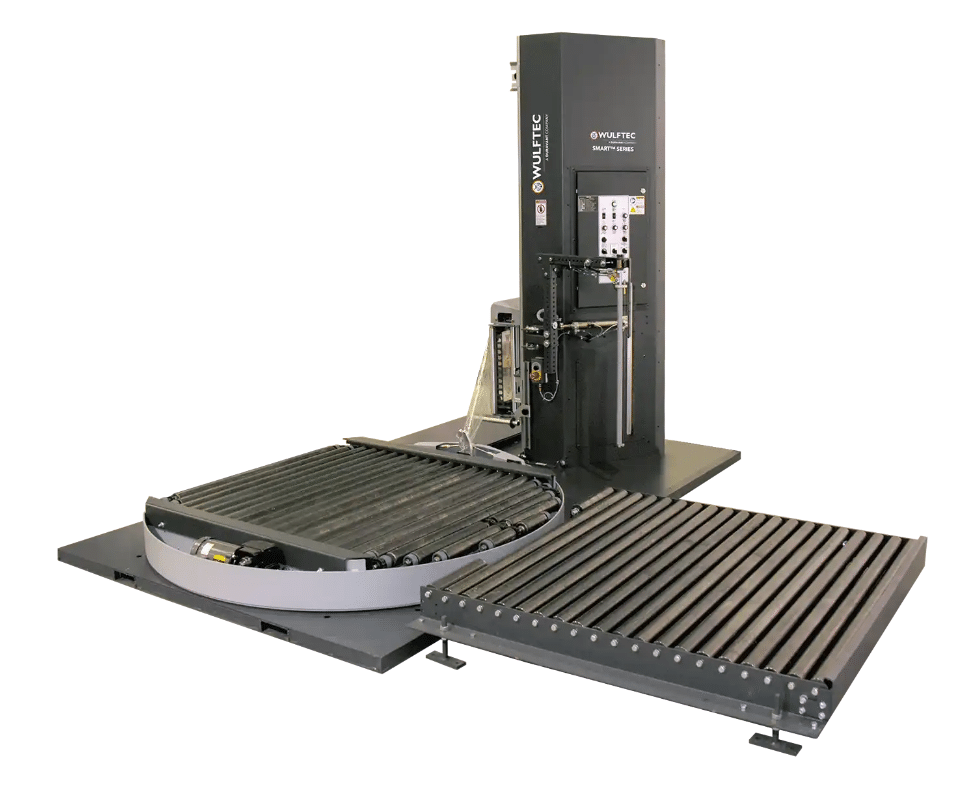

SMLCA-277 AUTOMATIC TWIN STATION CONVEYORIZED TURNTABLE STRETCH WRAPPING SYSTEM

Features:

- The Wulftec SMART™ Series is a competitively-priced series of semi automatic low and high profile turntable stretch wrapping systems… a smart approach to semi-automatic stretch wrapping

- With the SMART™ Series you get:

- the exact stretch wrapper you need and pay only for the features you want

- to pick and choose the individual components that will best meet your stretch wrapping needs

- a better, more competitive price

- better and quicker turnaround – now you don’t have to wait longer to get the exact machine you need – the SMART™ Series is modular in design

- to adapt without overspending

- The SMART™ Series has been designed to allow you to:

- upgrade the control panel at any time

- upgrade the base at any time

- upgrade the carriage at any time

- change the tower/wrap height at any time

- Wulftec was the first in North America to put AC variable frequency drives as standard equipment on all machines. Why? Lower maintenance and better reliability—Wulftec stretch wrappers will save time and money

- NEMA 4/12 control panel dust tight and waterproof

- The control panel is neatly organized eliminating time otherwise lost searching for wires

- The control panel is UL508A approved

- Superior Electrical/Electronic Design including Allen Bradley Micro800 Series and AC drives

- The pull cord remote allows the forklift driver to start and stop the machine. It includes 40 feet of cable and is activated by pulling once to start the cycle. A second pull would interrupt the cycle

- Easy to understand alarm signalization

- All motors, proximity sensors, photoeyes and other sensors have quick disconnect cables that simplify installation and maintenance

- Photoeyes are maintenance free and protected

- All Wulftec structures are made of heavy-duty steel for rugged performance, even in the harshest work environments. They’re built to last forever

- Dual chain driven for balanced movement & no vibration

- Quick and easy adjustment of upper and lower carriage travel

- The “Maintenance Free” spring loaded carriage gate equipped with spring loaded rollers, ensures optimal contact with the stretch film year after year, without involving maintenance

- Wulftec is the only manufacturer to offer a LIFETIME warranty on its pre-stretch rollers’ blue compound

- 50% to 300% pre-stretch ratio (preset to customer spec, Std 200%; capability up to 400% depending on film type)

- Since all of our semi-automatic SMART™ Series stretch wrappers wrap 2 inches from the turntable, you are guaranteeing the product is properly secured to the pallet, resulting in a pallet that is more stable for transport, and therefore less damage.

- No film threading is required and a Lexan cover eliminates operator’s ability to reach rollers when gate is closed

- The pneumatically operated cut and wipe-on system automatically cuts and wipes the film onto the load upon cycle end

- A vertical roller positions the film over the clamp which grabs the film; this ensures longer heat wire life expectancy

- Then the heat wire swings in and cuts the film

- A timed impulse heat control, allows quick cool down so the heat wire becomes cold to the touch within 5 seconds

- Wulftec’s clamp ensures clean film release from the pallet load.

- Non-Proprietary parts accessible on a local base

- The best warranties in the industry

- 5-year unlimited cycle warranty

- lifetime warranty on pre-stretch rollers

- 10-years on the steel structure

For more information about the machine and other stretch wrapping options please Contact Us at (416) 299-0960 and one of our customer service representatives would be happy to help you with whatever you need.