SMI BUNDLER / SLEEVE WRAPPER MODELS

| SMI BP800 | SMI BP800AS | |

|---|---|---|

| Power supply | 220-240 Volts/3 Phase | 220-240 Volts/3 Phase |

| Sealing Area | 30″ Wide | 30″ Wide |

| Max Product Height | 15″ | 15″ |

| Sealing Type | Hot Knife | Hot Knife |

| Max. Packing Speed | 10/Min | 10/Min |

| Max. Centerfold film | 21″ | 21″ |

| SMI BP802AS | SMI XP650 ALX | |

|---|---|---|

| Power supply | 220-240 Volts/3 Phase | 220-240 Volts/3 Phase |

| Sealing Area | 30″ Wide | 30″ Wide |

| Max Product Height | 15″ | 15″ |

| Sealing Type | Hot Knife | Hot Knife |

| Max. Packing Speed | 25/Min | 25/Min |

| Max. Centerfold film | 21″ | 25″ |

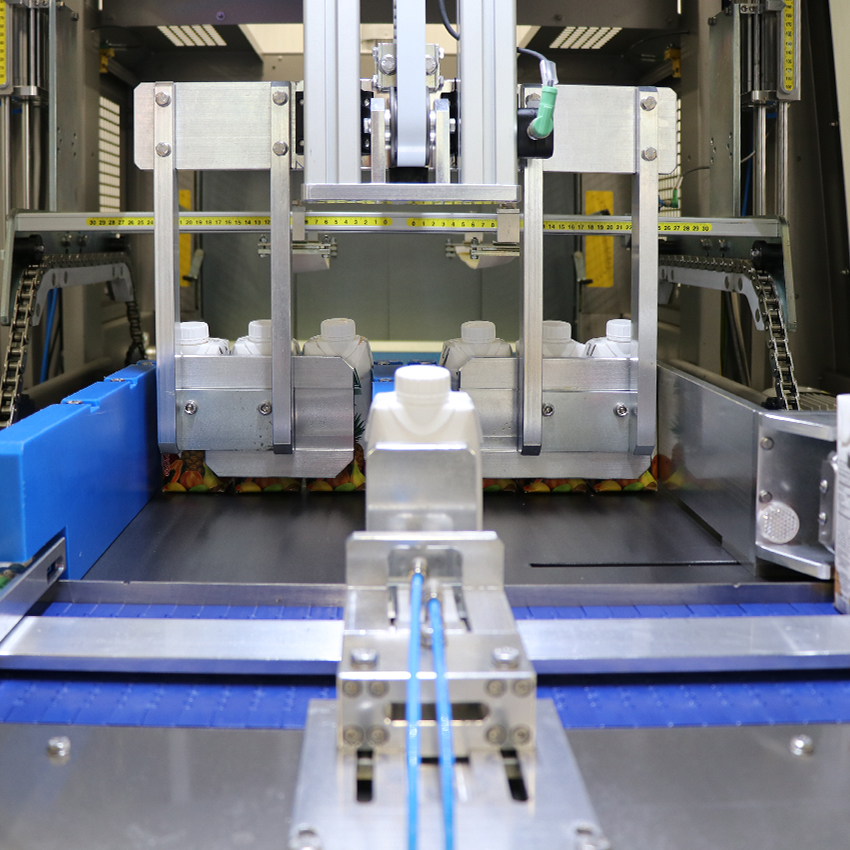

Standard Features:

- Automatic overlap shrink wrapper with in-line infeed conveyor

- Sliding protection doors with deceleration device

- Working modality: only film

- Double-chamber tunnel

- infeed and separator conveyors in-line with adjustable speed controlled by inverter

- Front infeed belt width 540 mm

- Machine available with left or right operator side

- Photocells for film wrapping, tunnel obstruction and outlet accumulation included

- Motorized lower film unwinding controlled by inverter and potentiometer

- Reel chuck with pneumatic locking

- Manual sealer of the reels

- Pneumatic film cut by cold blade

- Intermittent cutting cycle

- Film unwinding controlled by brushless servomotor

- Pack wrapping controlled by brushless servomotor

- Autoconfiguration of separation and wrapping of the pack

- Linking conveyor with adjustable speed controlled by inverter and encoder

- Included: feet for the machine fastening, press rod to stop products, cooling fan at the tunnel outlet

- Automatic, semiautomatic, pass through mode

- Metric graduation based film reels centering system

- Tunnel belt with adjustable speed controlled by inverter

- Tunnel air flow adjustable by means of independent deflectors

- Tunnel conveyor with glass fibre bars (SMI patent in use concession)

- Oven cooling system

- FLXMOD® control system equipped with:

- operator Interface 7″ full-colour touch screen sliding all along the length of the machine

- PLC

- inverter with integrated encoder reading

- IN/OUT control modules

- Storing of 50 different working cycles

- 4.0 industry compliant

- Compliance with CE regulations

For more information about the machine and other shrink packaging options please Contact Us at (416) 299-0960 and one of our customer service representatives would be happy to help you with whatever you need.