Features and Advantages:

- Continuous cycle sealing

- Pack deviation device

- Film waste winding device as standard supply

- PTFE-coated sealing blade

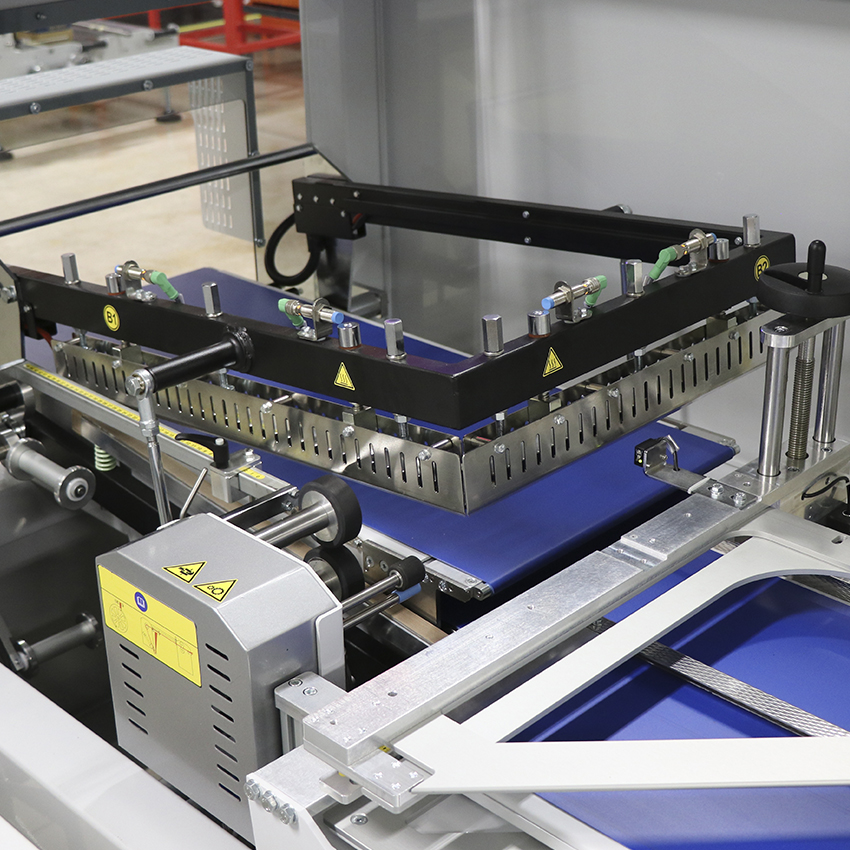

- Closed-circuit liquid cooling of the sealing bars

- Viewer of the coolant level

- Working height of the sealer and of the tunnel adjustable by means of an external crank

- Mobile product-holding plate, loose from the film reel support to allow a better adjustment of the film to the pack size

- Emergency button

- Automatic pack discharge by means of a motorized conveyor

- Reduced power consumption

- Compliance with CE regulations

- Reduced power consumption

- Compliance with CE regulations

Flextron® control system equipped with:

- Alphanumeric LCD control panel provided with a 16-bit microprocessor card and solid state relays

- Modular power section, separated from the control panel and characterized by:

- longer-lasting solid state relays providing easier maintenance

- in case of failure, possibility of replacing just the damaged module, without losing the data stored in the memory

This system allows a simple and precise control of all the machine operations, such as:

- machine status

- number of packs produced by an electronic pack counter

- real-time production

- adjustment of the sealing temperature

- pack discharge speed

- automatic hood closing and re-opening, motorized and managed by inverter

- delay in the opening of the sealing arm

- sealing arm safety device

- possibility of scheduling up to 10 different work cycles, thus resulting in increased productivity and simplified use

- troubleshooting

For more information about the machine and other shrink packaging options please Contact Us at (416) 299-0960 and one of our customer service representatives would be happy to help you with whatever you need.