The FPS 400L is Designed for Efficient and Reliable Pallet Wrapping

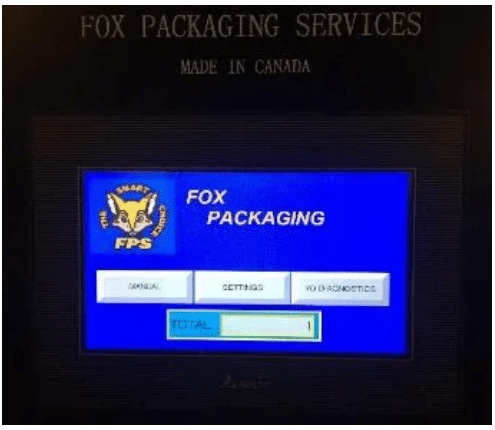

Control Features:

- 32 I/O PLC (Programmable Logic Control) by DELTA

- Full color 7” touch screen display by DELTA (providing function control viewing)

- DELTA 1 HP AC VFD’s

- Variable Turntable Speed 0-15 RPM

- Variable Film Carriage Speed Up/Down Control

- Separate Top/Bottom Wrap Selectors 1-9

- Separate Film Height Selector 1-9″

- Flush Mounted Control Panel (built into tower)

- Cycle Counter

- Manual Carriage Raise/Lower Control

- Turntable Jog with Auto Home Alignment

- Large Emergency push button power On/Off

- Switch with indicator light

- Start Cycle Push Button

- 3 different on board wrap programs

- All circuits protected by fuses (easy access)

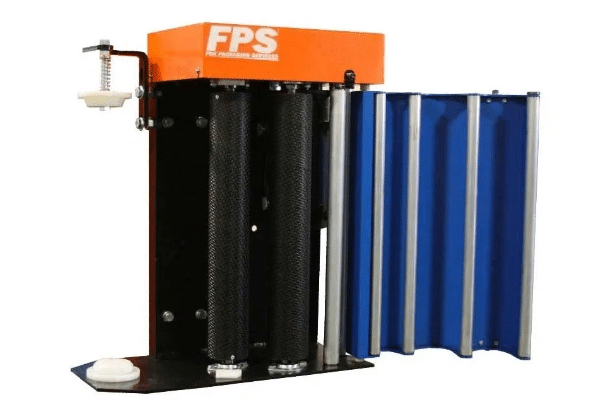

Film Deliver System:

- HURRICANE THREAD© 20″ prestretch film delivery system

- 200% factory set film stretch (50%-250% available upon request)

- Easy thread film carriage

- Electronic film force control on panel

- Adjustable mechanical force to load

- Linear analog proximity sensor film feed speed control

- 3/4HP AC MOTOR & DELTA 1 HP VFD variable speed film drive

- Triple beam auto height eye capable of recognizing all colors including black

THE FPS 400L HAS A BUILT IN PATENTED END OF CYCLE FILM CUTTER AT NO EXTRA COST.

A UNIQUE TOTAL MECHANICAL DEVICE THAT WORKS EVERY TIME AND BUILT TO LAST WHICH ELIMINATES THE NEED FOR KNIVES PLUS IT’S ONE LESS FUNCTION THE OPERATOR IS REQUIRED TO PERFORM.