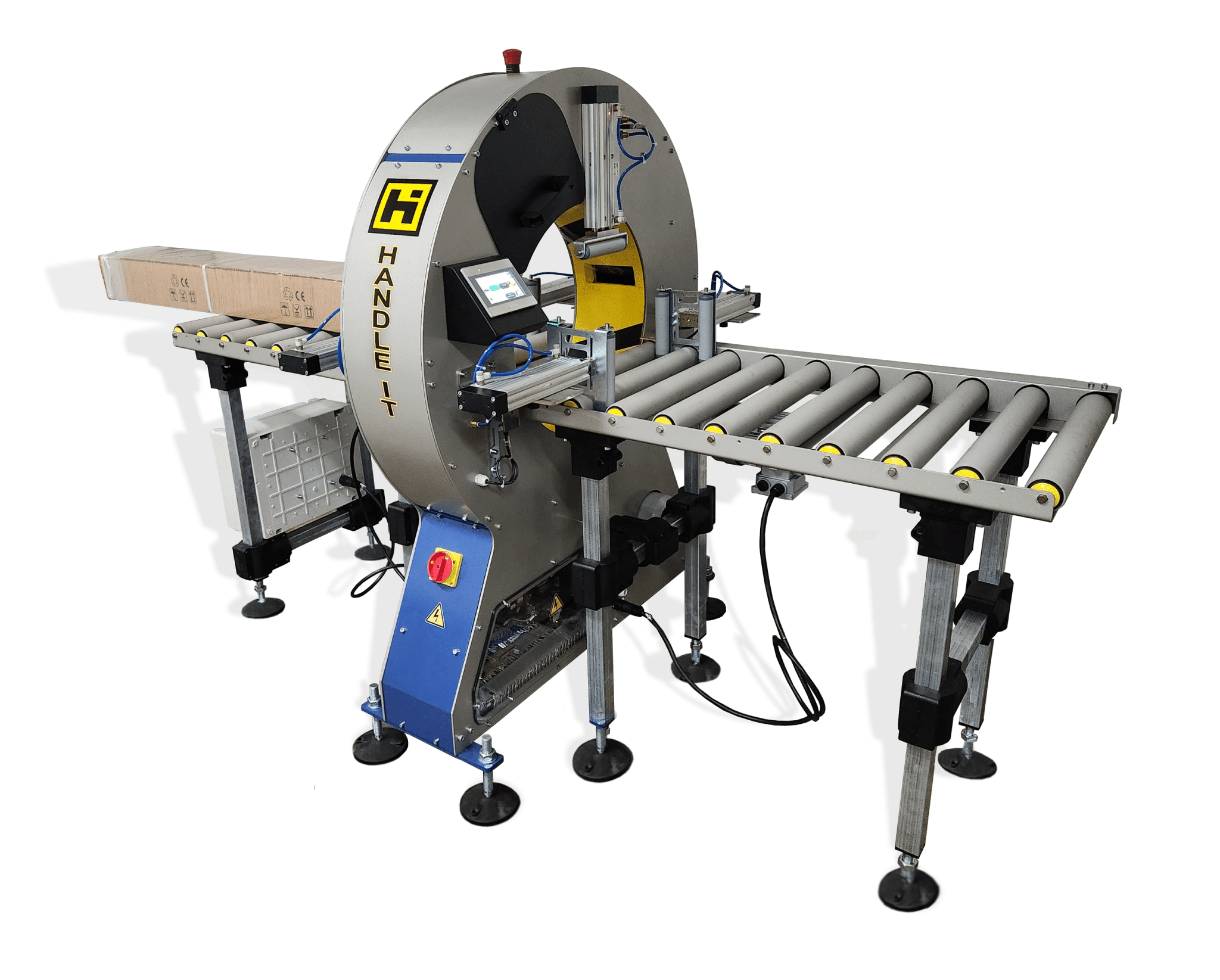

OFFERS FAST AND EFFICIENT WRAPPING FOR OVERSIZED AND IRREGULARLY SHAPED PRODUCTS

Overview:

- Double reel dispenser head; allows to wrap with two reels of stretch film for a reinforced wrapping and faster packaging or to wrap with one reel for a simple wrapping; ready to use reels of different width.

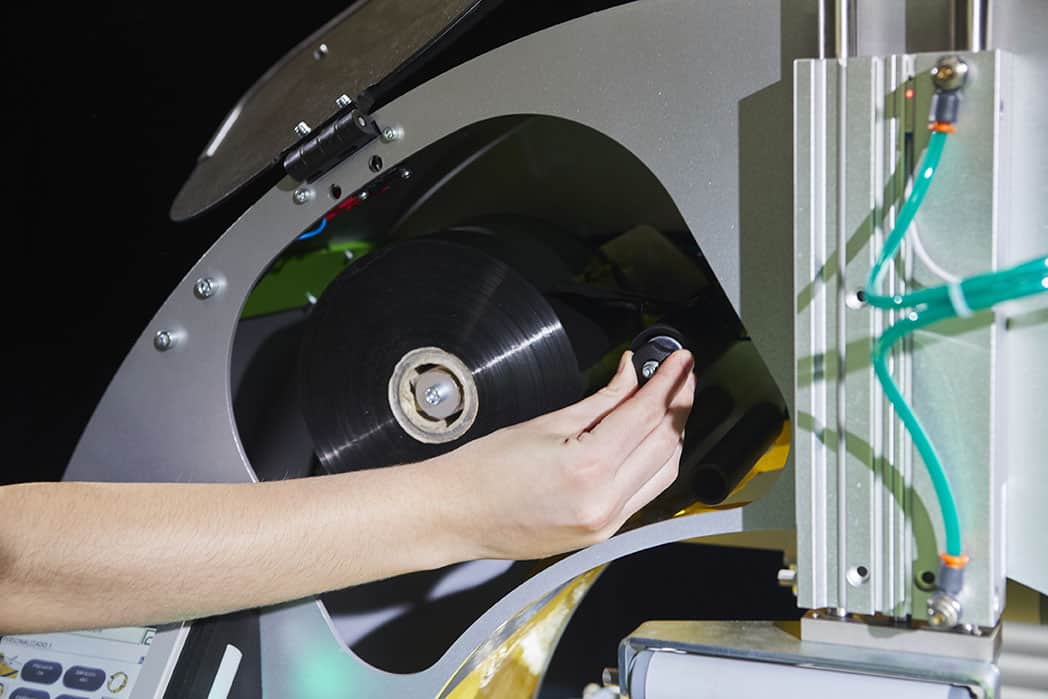

- Fast changing reels without tools and with self-fixing system.

- Adjustable stretch film tension to fit it to the product.

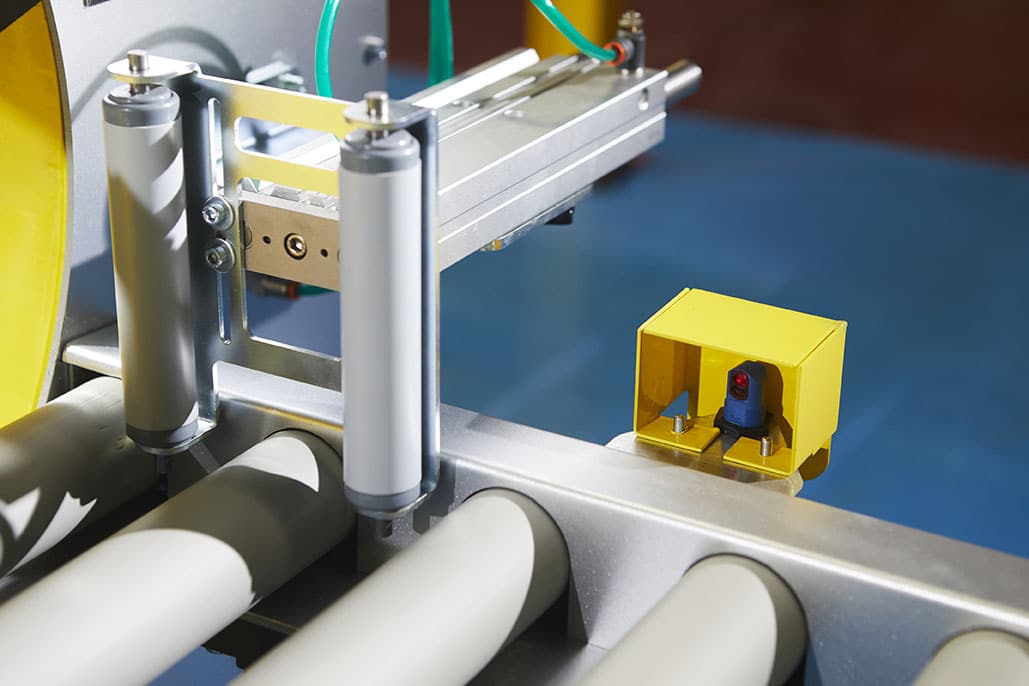

- Double automatic stretch film clamp and cutter system for two reels; cuts even with zero tension and has a blade protector for user safety.

- Automatic stretch film threading for reel changing.

- Stopping system to place the reel dispenser head in the exact position for reel changing.

- Device that unable the machine to work while changing the reel for user safety.

- Ring driver system through trapezoidal belt.

- Ring speed controller to adjust working speed or stretch film overlap onto the product.

- Adjustable extra wrapping laps in both ends of the product for a higher protection.

Interactive color touch screen, integrated in the front of the machine to program and adapt the wrapping machine to the needs of the product to be wrapped with:

- Wrapping programs (9): 1 to 4 – Complete wrapping (from one product end to the other), 5-Only ends, 6-Banding, 7-Complete with intermediate banding, 8-Semi-automatic and 9-Only conveyors.

- Display of messages, explanatory gif videos, change of reel, regulation of extra laps at product ends, on/off top presses (optional), up & down top presses regulation time (optional), distance between banding, warning preventive maintenance and programmable in 3 languages.

- Option to eliminate film tails in the product start.

- Screen lock with password to avoid inappropriate manipulations of the chosen parameters.

- Integrated electrical cabinet and illuminated with led, to facilitate operations; incorporates master switch.

- Led warning light to inform status of orbital wrapper (operative, working or emergency).

Accessories:

- Infeed & outfeed top pressers – manual fitting.

- Infeed & outfeed top pressers – automatic fitting, includes electrical photocell to detect product outfeed.

- Side vertical rollers, manual fitting, to guide and/or to group the product.

- Side vertical rollers, automatic fitting (pneumatic), to guide and/or to group the product

- Driven conveyor metal rollers 20″ x L40″ (other dimensions also available).

- Driven conveyor belt 23″ x L40″ (other dimensions also available).

- Driven conveyor metal rollers “V” shape 23″ W x 79″ L.

- Automatic driven system to load laterally the product to be wrapped.

- Automatic pneumatic system to remove the wrapped products laterally.

- Automatic driven system to remove the wrapped products laterally.

- Wheels with brake.

- Short products bridge <20″

- Warning of stretch film reel end.

- Warning of stretch film breakage.

- Outfeed conveyor electrical photocell to block the machine until product is remove.

- Safety fences + safety kit.

- Manual bubble wrap floor dispenser for reel up to 23″

- Automatic top & bottom bubble wrap reel dispenser up to 40″ W, includes:

- Welding bar by electrical resistances to join the ends of the top and bottom bubble wrap reels.

- Welding temperature control to adjust the temperature depending on the bubble wrap thickness.

- Top and bottom bubble wrap reel dispenser; top reel to cover top side product length and bottom reel to cover bottom side product length.

- Electrical photocell to start automatically the wrapping cycle.

- Driven feeding of top and bottom bubble wrap reels, to avoid product pulls directly from them.

- Selector to cancel the automatic dispenser and to allow machine wrapping with stretch film only.

- Tower lights to inform status of dispenser.

Available Options:

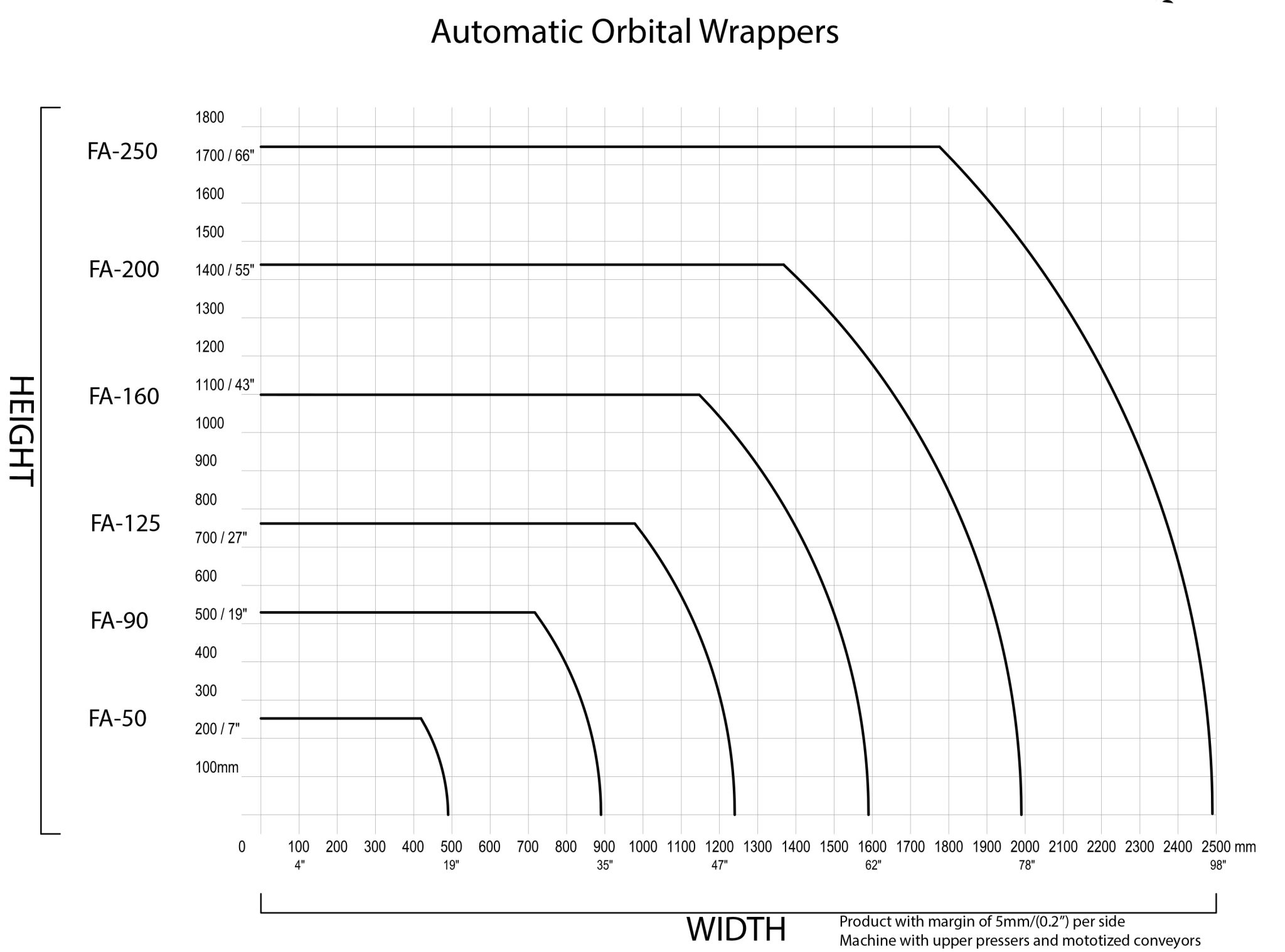

Review the chart below to choose the proper size wrapper for your products:

For more information about the machine and other orbital wrapping options please Contact Us at (416) 299-0960 and one of our customer service representatives would be happy to help you with whatever you need.