Palletizers

Bring speed and consistency into your distribution Centre with a TOPTIER palletizer

The reliability and pioneering technology of TopTiers palletizing solutions are widely acknowledged in the packaging industry, playing a crucial role in automated end-of-line packaging operations for manufacturers of food, beverage, and consumer packaged goods.

Small Footprint

Peak Consistency

Complete Automation

Unparallel Speed

HIGH INFEED PALLETIZER

High infeed case palletizer model groups share common functional modules and frame systems to provide comprehensive palletizer solutions. Shared modules maximize layout flexibility while reducing cost through increased manufacturing and machine controls efficiencies. Modular engineering means quality control and complete flexibility in the configuration of machine components. No customization is required.

VALUE PALLETIZER

Smallest footprint in the market: Robotic palletizing has become an increasingly accepted alternative to traditional layer palletizing, but the solution is not without challenges. Typical generic robotic palletizers experience limits on products that can be handled, performance issues with deviations in product uniformity, special training to handle complexities of robot programming, large footprint, custom integration, and the expense of support.

LOW INFEED PALLETIZER

Palletizer model groups share common functional modules and frame systems to provide comprehensive palletizer solutions. Shared modules maximize layout flexibility while reducing cost through increased manufacturing and machine control efficiencies.

Modular engineering means quality control and complete flexibility in the configuration of machine components. No customization is required with our low level palletizers. The orientation of induction and load exit meet your exact requirements.

ROBOTIER HYBRID PALLETIZER

The low infeed RoboTier utilizes end of arm tooling, allowing higher speed robot motion and advanced product handling security. Bottom support offers a significant improvement over typical robot product handling methods such as vacuum top picking that is less flexible and secure, and is ideal for bagged product.

Module options include concurrent stretch wrap, pallet handling, sheets and liners, and load handling. Safety category 3 PL-d per EN ISO 13849-1 based on controlled entrance protocols. 1-3 layers/min. Every product type, including case, bag, tray, trayless, open top, lidded, overwrapped or unwrapped, bundles, nested, display pack, totes, and more.

ROBOTIER ROBOTIC PALLETIZER CELLS

Robotic palletizer cells offer wide layout flexibility and are engineered from experience.

RoboTier utilizes end of arm tooling that supports product from the bottom, allowing higher speed robot motion and advanced product handling security. Bottom support offers a significant improvement over typical robot product handling methods such as vacuum top picking that is less flexible and secure, and clamping systems that necessitate looser loads.

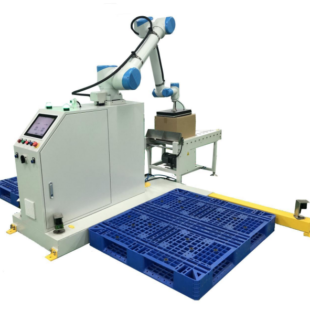

ALPHA-ROBOT PALLETIZER

The Palletizer Workstation is an advanced small goods-handling system designed for industries such as food, medicine, 3C (computer, communication, and consumer electronics), printing, and daily chemicals. This system is remarkably user-friendly, with a visual programming interface that takes just five minutes to set up. Once the necessary information is entered, it can quickly begin stacking products or cartons onto pallets, enabling fully automated handling.

This intuitive visual programming interface makes the robot easy for any operator to control. Designed for high loads, it can lift products up to 20kg. Its compact size and simple wiring allow deployment in various environments. The machine is highly efficient, requiring minimal maintenance, and can stack 5 to 10 boxes per minute.

How we can help

Increase Productivity

Focus on Sustainability

Reduce

Costs

Reduce

Waste

Increase Throughput

Customer Satisfaction

contact us today!

Have a question about packaging machine equipment or service?

Give us a call or send us a message with the form below. One of our customer service representatives would be happy to help you with whatever you need.

impak packaging

110A Iron St.

Etobicoke, Ontario

M9W 5L9

Phone: 416-299-0960

Fax: 416-299-0961

Email: info@impakpackaging.com

INQUIRIES

info@impakpackaging.com

416-299-0960

parts & service

servicing@impakpackaging.com

416-299-0960