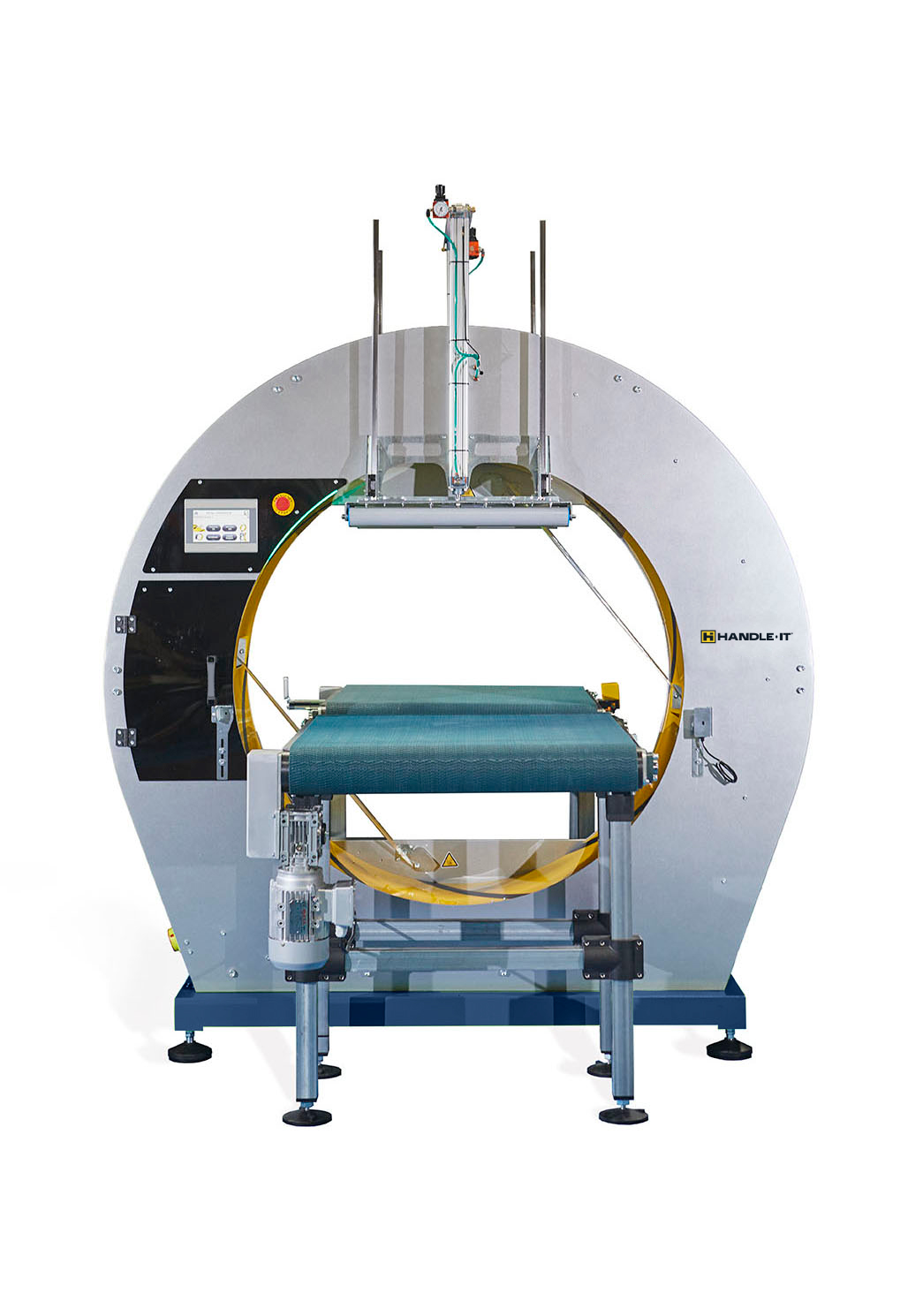

PROVIDES ROBUST AND EFFICIENT WRAPPING SOLUTIONS

Overview:

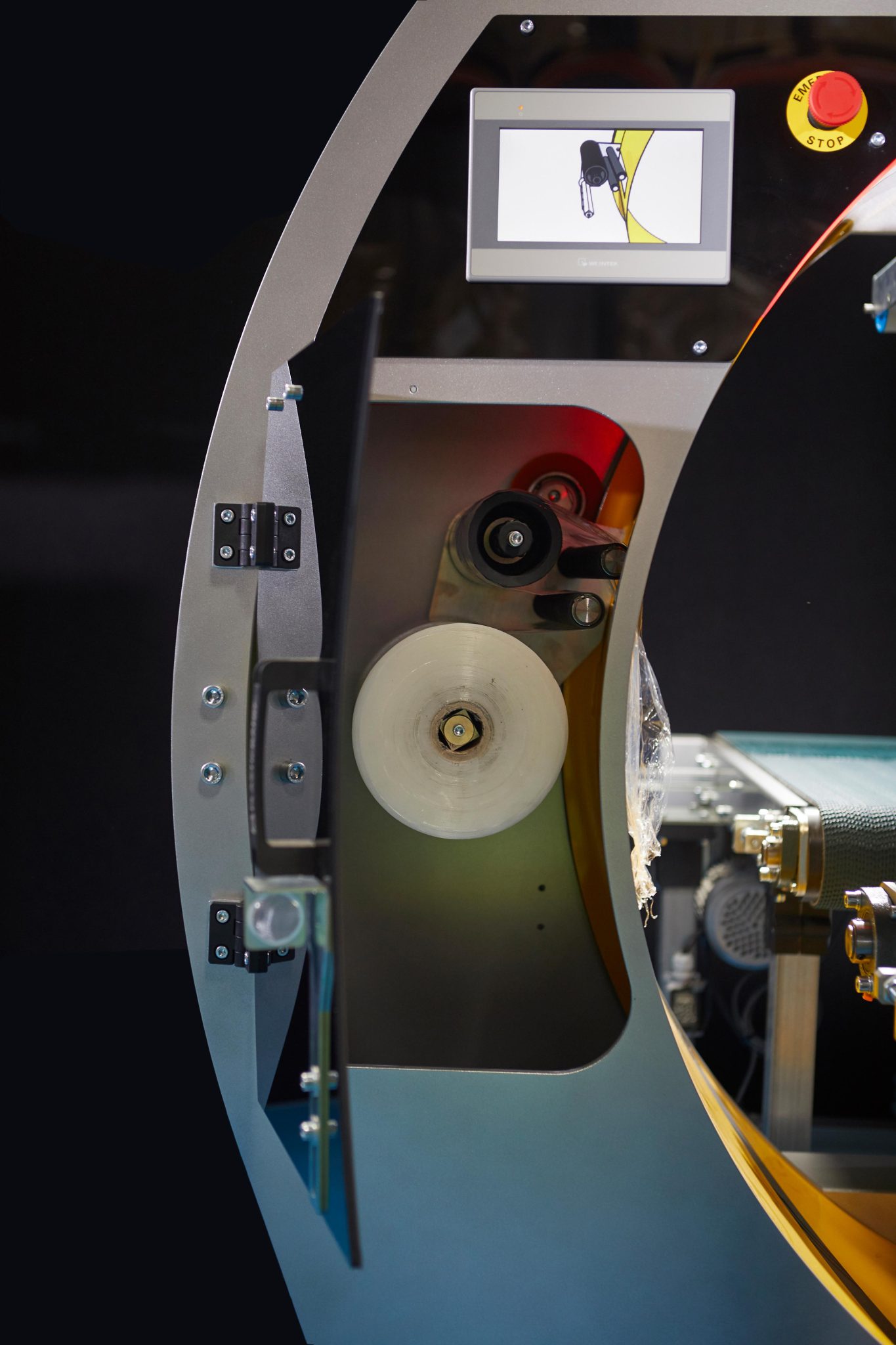

Standard equipment:

- Steel frame, painted in grey with blue accent color.

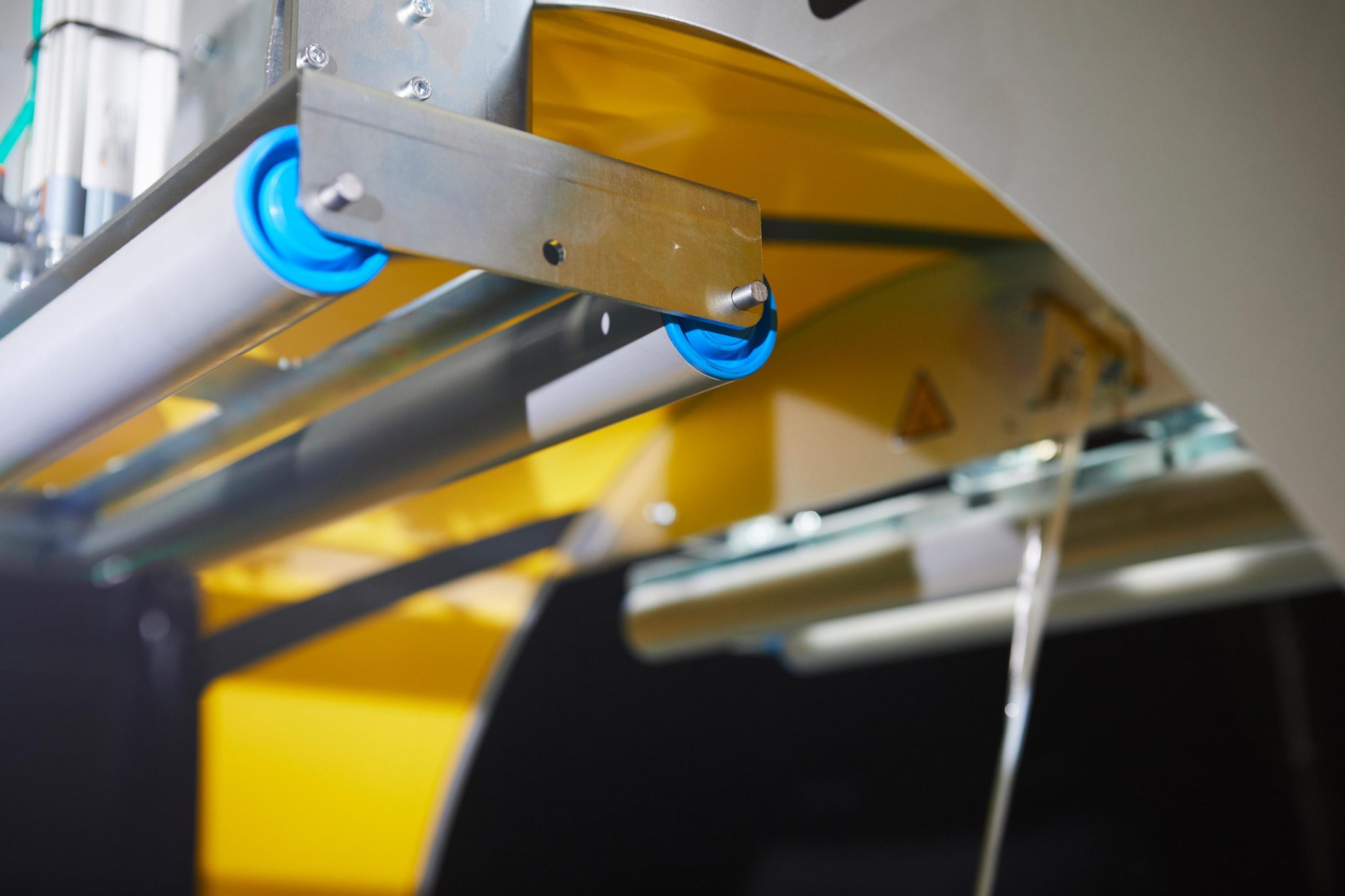

- Covered ring wrapping mechanism for added safety, painted safety yellow.

- Double reel dispenser head; enables wrapping with two reels of stretch film for reinforced and faster

packaging, or wrap with one reel for a simple wrap; ready to use reels of different width. - Fast changing reels without tools and with self-fixing system & automatic stretch film threading.

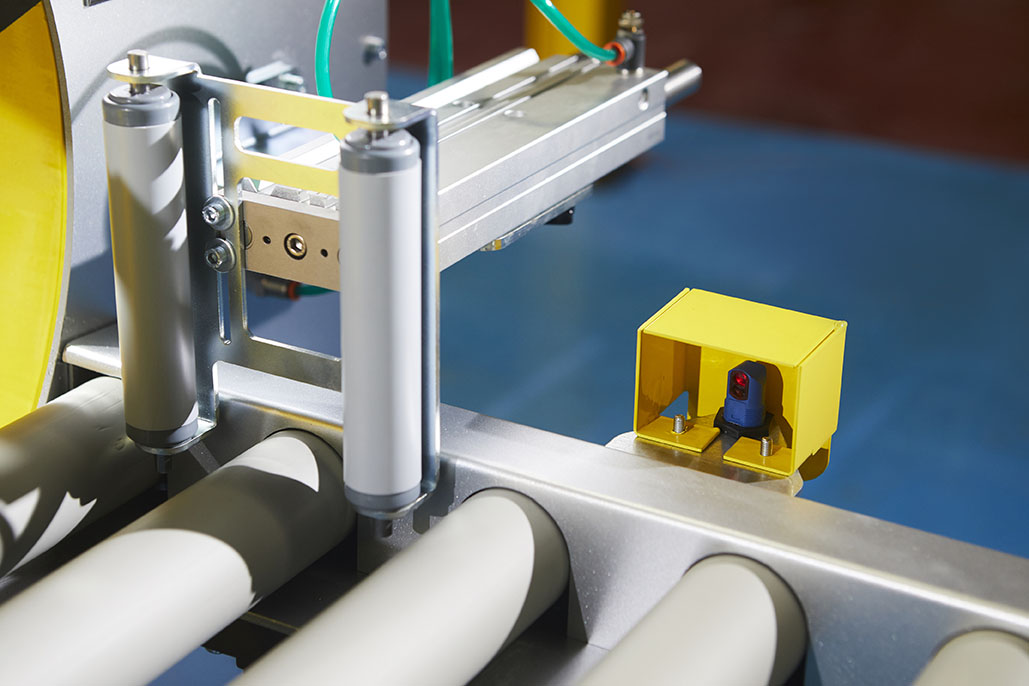

- Double automatic film clamp and cutter system for two reels; cuts even with zero tension &

has a blade protector for user safety. - Adjustable stretch film tension to fit it to the product.

- Device that disables the machine while changing the reel for worker safety.

- Ring speed controller to adjust working speed or stretch film overlap onto the product.

- Ring driver system through trapezoidal belt with low maintenance and wear.

- Adjustable extra wrapping laps on both ends of the product for greater protection.

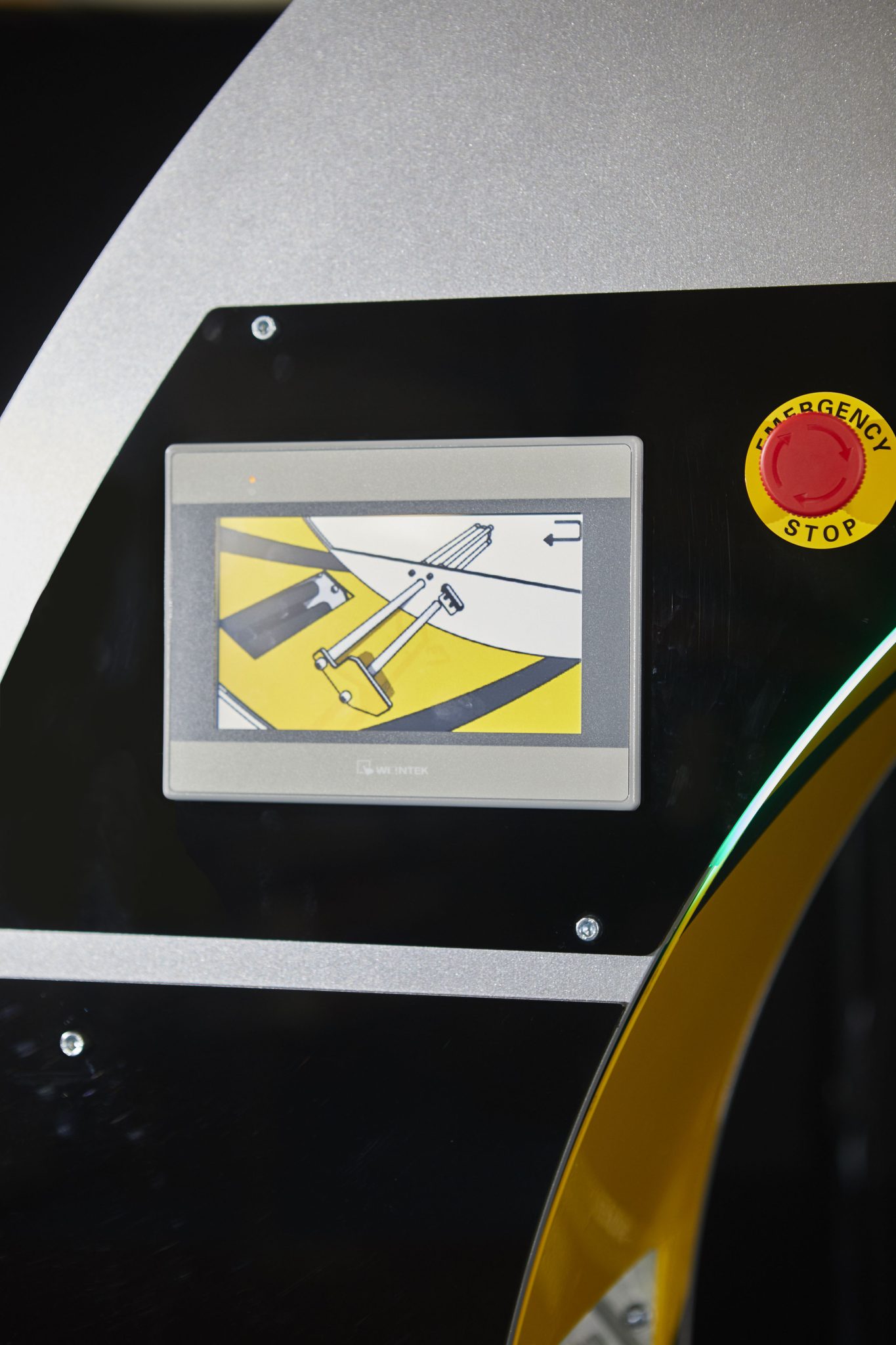

- Interactive color touch screen enables programming the unit to the needs of the product:

- Wrapping programs (9):

1 thru 4 – Complete wrapping (from one product end to the other), 5-Only ends,6-Banding,

7-Complete with intermediate banding, 8-Semi-automatic and 9-Only conveyors.

-Display of messages, explanatory gif videos, change of reel, regulation of extra laps at

product ends, on/off top presses (optional), up & down top presses regulation time (optional),

distance between bandings, preventive maintenance warning. - Option to eliminate film tails in the product start.

- Screen lock with password to avoid inappropriate manipulations of the chosen parameters.

- Wrapping programs (9):

- Electrical photocell to start wrapping cycle.

- Integrated electrical cabinet, illuminated with LED, to facilitate operations; incorporates master switch.

- LED warning light to inform status of orbital wrapper (operative, working or emergency).

- Machine certificate meeting CE safety standards (2006/42/CE 2014/30/UE 2014/35/CE-BT).

Accessories:

Customize your machine:

- Infeed & outfeed top pressers – manual fitting.

- Infeed & outfeed top pressers – automatic fitting, includes electrical photocell to detect product outfeed.

- Rollers side guide – manual fitting.

- Driven conveyor belt W31.5″ x L39″ (other dimensions also available).

- Driven conveyor metal rollers W31.5″ x L39″ (other dimensions also available).

- Driven conveyor chain W31.5″ x L39″ (other dimensions also available).

- Driven conveyor belt with pneumatic lift to place corners W39″ x L98″.

- Driven conveyor metal rollers “V” shape W47″ x L157″

- Gravity rollers conveyor + tilter system to place product from vertical to horizontal W47″ x L59″.

- Table with 4 driven rollers in cross, with pneumatic lift, to wrap round products.

- Table with 2 driven in parallel to wrap round products.

- Hydraulic lift table to center the machine ring vs conveyors.

- Short products bridge <23″.

- Driven conveyor belts (bridge) W45″ x L23″ for short products <23″.

- Wooden/porex blocks automatic dispenser (not included driven conveyor for short products W45″ x L23″).

- Warning of stretch film reel end.

- Warning of stretch film breakage.

- Safety fences + safety kit.

- Manual bubblewrap top dispenser (integrated on machine) for reel up to 47″.

- Manual bubblewrap floor dispenser for reel up to 47″.

- Double automatic dispenser for bubble plastic · foam · polyethylene”

Available Options:

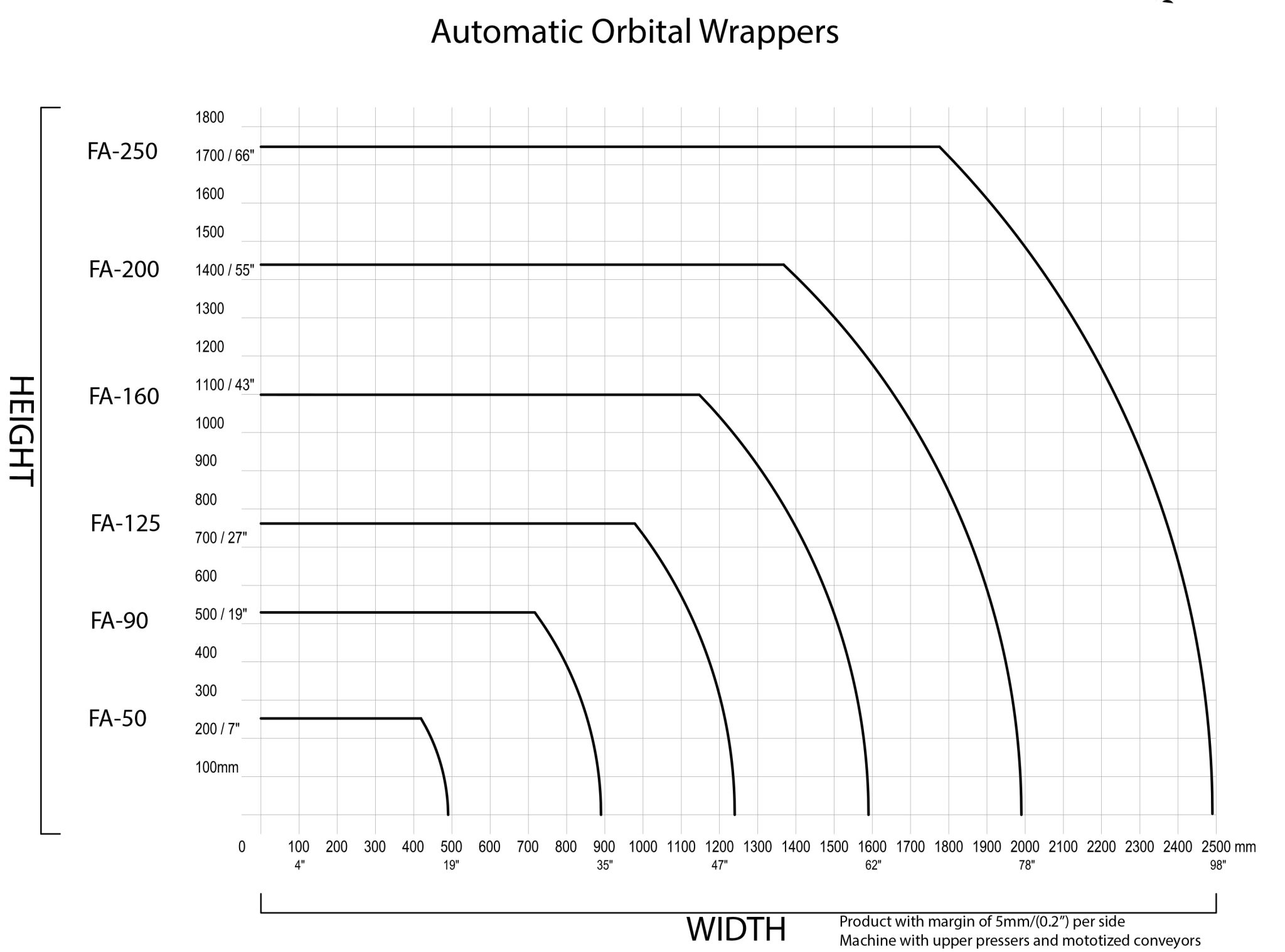

Review the chart below to choose the proper size wrapper for your products:

For more information about the machine and other orbital wrapping options please Contact Us at (416) 299-0960 and one of our customer service representatives would be happy to help you with whatever you need.