Packaging Machine parts & BESt-IN-class service

416-299-0960

PACKAGING MACHINE SERVICES

services we offer

Moreover, we prioritize safety by ensuring that all equipment is CSA certified, meeting the necessary standards for Canadian installations. By maintaining close collaboration with our customers, we strive to accommodate their timelines and ensure optimal operational efficiency of the equipment.

Follow-up

Within 1 to 2 weeks of training, we conduct a follow-up visit to ensure smooth operations. Our team verifies correct and safe equipment usage and addresses any questions.

Routine inspection and maintenance of packaging equipment is recommended for both new and older machines. Often, smaller issues can lead to larger ones and routine maintenance is an effective way of preventing this.

Common Issues

Most problems are not related to machine failures, but rather to process changes. The machine is created as simple as possible. However, set-ups and adjustments are usually required:

• Moving parts are not operating smoothly

• Testing machine benchmarks

• Equipment slowdowns

• Equipment/systems re-calibration

• Essential fluid changeovers

Benefits of Preventative Maintenance

Participating in regular maintenance check-ups can benefit customers in many ways:

- Enhanced safety

- Longer product life

- Decreased downtime & increased reliability

- Consistent efficiency levels

Maintenance needs have lowered drastically as new automatic machines use less parts. Older machines would have mechanical systems that would move the shafts & bearings and pulleys. Today we have a motor connected to a shaft that drives each one of those components. Belts instead of chains. Smoother, quieter, and much more controlled. Servo driven – electrical machines.

We provide an on-going maintenance program specifically tailored to older machines, as well as the newer more sophisticated machinery. Additionally, our after sales service is only a phone call away.

PACKAGING MACHINES WE WORK ON

At Impak Packaging, we proudly supply parts from leading manufacturers such as Shanklin, Wulftec, SMI, BestPack, Fox, Highlight, Heat Seal, and many more. We are committed to providing high-quality parts and exceptional customer service to help you maintain reliable, efficient packaging operations.

OUR PREVENTATIVE MAINTENANCE PROGRAM

Protect Your Packaging Line from Costly Breakdowns

Book a preventative maintenance program today and avoid unplanned downtime. Taking care of your equipment today means fewer breakdowns tomorrow. Our Preventative Maintenance Program is designed to keep your machines running longer, safer, and more efficiently—saving you time and money in the long run.

-

Benefits

-

Scope or Work Performed

-

Service Time

-

Other

- Decrease in equipment downtime and the number of major repairs reduced.

- Better management of assets and increased life expectancy, thereby eliminating premature replacement of machinery and equipment.

- Reduced overtime costs and more economical use of maintenance workers, due to working on a scheduled basis instead of a crash basis to repair.

- Timely, routine repairs circumvent fewer large-scale repairs.

- Improved safety and quality conditions for everyone.

- Inspect, clean, adjust and lubricate chains and drive system.

- Clean and inspect load casters/rotary arm pinion.

- Inspection, adjustment and lubrication of gears and chains.

- Check functionality of limit switches, photo eyes and reflectors.

- Check functionality of all safety devices, guarding and E- stops.

- Ensure all indicator lights are functional and replace any burnt bulbs.

- Thorough visual inspection of wiring and overall machine condition.

- Discuss operational issues with Key Operators.

- Clean exterior of machine and sweep service area.

- Provide detailed explanation of recommended/necessary repair or replacement parts.

- Leave contact information for future communications.

- Minimum 2 Hours (Include 1 Hr. Travel time within GTA) for semi-automatic machinery.

- Better management of assets and increased life expectancy, thereby eliminating premature replacement of machinery and equipment.

- Flexible scheduling available to reduce downtime during peak production hours.

- Rapid response options available for emergency service calls—minimizing production disruption.

- For travel time outside GTA, actual time spent will be charged both ways.

- Replacement parts & repairs will be at additional cost.

- Infeed & Outfeed systems will be service & repaired at additional cost.

- Custom service agreements available upon request for multi-site or high-volume operations.

Trusted Parts from Leading Packaging Brands

At Impak Packaging, we proudly supply parts from leading manufacturers such as Shanklin, Wulftec, SMI, BestPack, Fox, Highlight, Heat Seal, and many more. We are committed to providing high-quality parts and exceptional customer service to help you maintain reliable, efficient packaging operations.

packaging machine parts

We source only the highest quality packaging equipment parts for a large variety of packaging machinery so that you have exactly what you need, right when you need it. We know what’s best for you and your machines.

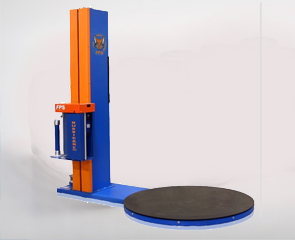

- Stretch Wrapper Parts

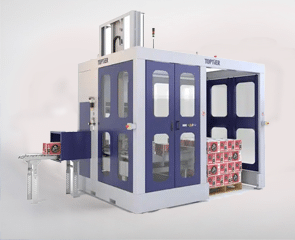

- Shrink Tunnel Parts

- Case Sealer Parts

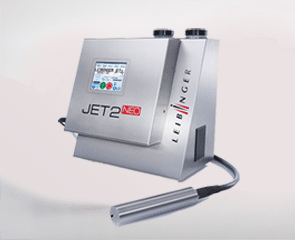

- Ink Jet Printer Part

- Labelling Machine Parts

- Silicone Heat Pads

- Teflon Tape Parts

- Ink Jet Printer Parts

- Labeling Machine Parts

- Stretch Wrapper Parts

- Shrink Tunnel Parts

- Case Sealer Parts

- Ink Jet Printer Part

- Labelling Machine Parts

- Silicone Heat Pads

- Teflon Tape Parts

- Ink Jet Printer Parts

- Labelling Machine Parts

why choose impak?

Top Technicians

Our technicians deliver complete service, parts, and training support to keep your equipment running at peak efficiency.

Experience

With over 20 years of experience servicing packaging equipment, our technicians provide quick turnaround and reliable performance.

Industry Leadership

As a national leader in end-of-line packaging, Impak Packaging sets the standard for service excellence, trusted by manufacturers across a wide range of industries.

Continued Growth

Our service department is expanding—adding new technicians, investing in training, and improving response times to support more customers across diverse industries.

THE TEAM

Meet Our Team

Chris Tremblay

Implementation EngineerDon Chung

Service Cordinator, Technical SalesJeff Martin

Lead Automation SpecialistMike Iacobucci

Automation SpecialistContact Us Today!

Looking for Packaging Machinery servicing or Parts?

Just give us a call or send us a message with the form below. One of our customer service representatives would be happy to help you with whatever you need.

400 Flint Rd.

North York, Ontario

M3J 2J4

Phone: 416-299-0960

Fax: 416-299-0961

Email: [email protected]