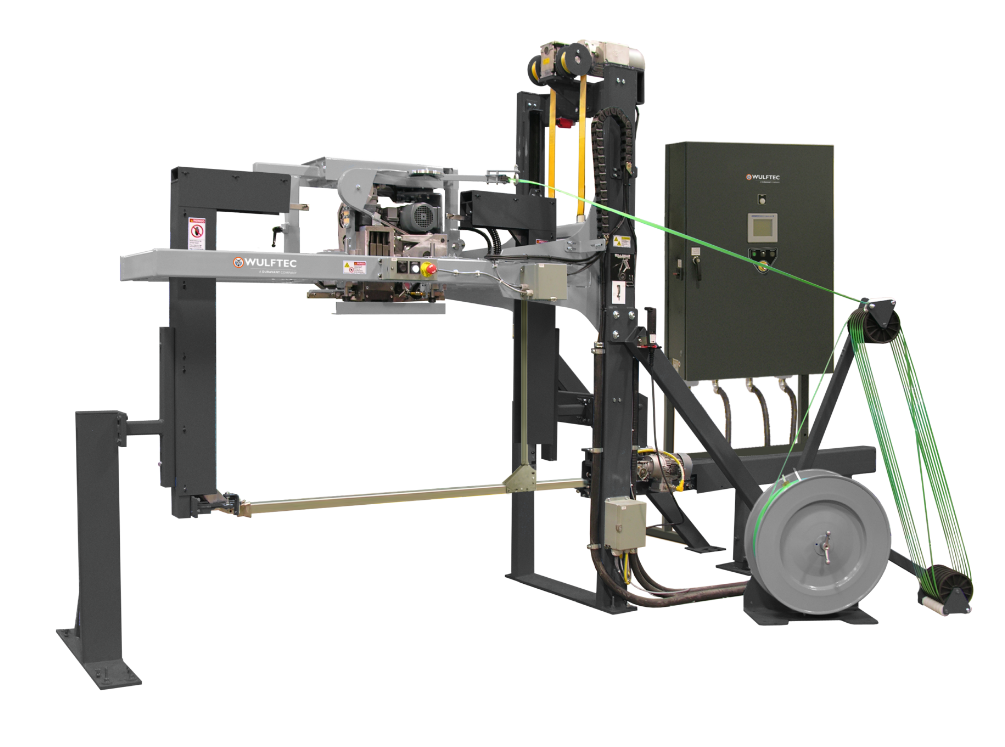

VARIOMASTER 9469 STRAPPING SYSTEM

Features:

- Control panel is UL508A approved

- 100% heavy duty structural steel construction

- Superior electrical/electronic design including Allen Bradley PLC logic control

- Allen Bradley touch screen

- Strapping head is top mounted in the platen for easy access for service or maintenance

- Platen up/down motion electrically driven by nylon belts

- Vertical strappers available with pallet bayonet and/or under track

- Strap dispenser with pulley block, strap return storage with electric brake

- Up to 5 straps per minute may be applied, depending on strapping arch and package dimensions, strap quality and strap tension required

- Any brand of PET strapping may be used without any special adjustment to the strapping head

- Dry contact communication to apply the strap

- Two fully customizable strap patterns on touch screen

For more information about the machine and other strapping options please Contact Us at (416) 299-0960 and one of our customer service representatives would be happy to help you with whatever you need.