Overview

TECHNOLOGY

RoboTier utilizes end of arm tooling that supports product from the bottom, allowing higher speed robot motion and advanced product handling security. Bottom support offers a significant improvement over typical robot product handling methods such as vacuum top picking that is less flexible and secure, and clamping systems that necessitate looser loads.

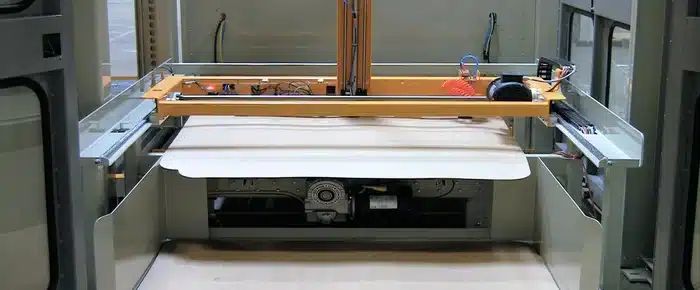

Bottom support is achieved by assembling layers on an apron with products loosely spread to allow removal of the bottom support tool. Loose spreading allows faster robot speeds, as exact product placement is not critical. Once a layer is completed, four-sided clamping centers the layer on the pallet and a tight uniform layer is deposited. Vertical travel capabilities of the apron reduce robot reach requirements allowing use of the smaller, faster, and more economical Fanuc robots. The layer apron also provides a queuing platform for continued layer building while optional concurrent stretch wrapping occurs.

CONTROLS

RoboTier product handling innovations are enhanced by advanced controls architecture for robotic palletizing systems. A Fanuc controller with very simple code that cannot be modified directs robot motion based on PLC instructions. In effect, the robot is an electronic slave to the Allen Bradley CompactLogix PLC master controller and B&R PC 12″ color touchscreen HMI. All automatic and manual palletizer functions are controlled using the HMI touchscreen; robot controls training or experience is unnecessary. EasyStack programming software installed on the PC HMI creates patterns quickly and easily without PLC or robot programming.

For more information about the machine and other palletizing options please Contact Us at 647-735-4411 and one of our customer service representatives would be happy to help you with whatever you need.