Key Features

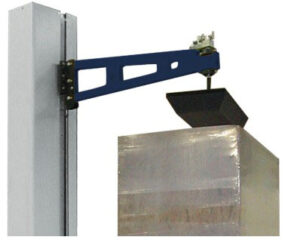

AUTO FILM CLAMP

Highly reliable, dual rod cutting system fully automates the wrapping process.

MULTI-LEVEL VARIABLE CONTAINMENT FORCE

Delivers optimal containment force at each level. Containment force is adjustable up to 9 times on each load.

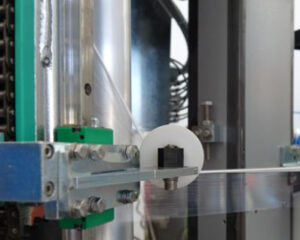

MULTI-LEVEL VARIABLE PRE-STRETCH

Ensures the best film economy for every load. Adjust the pre-stretch up to 9 times on each load. Multi-Level Variable Pre-Stretch Technology delivers 30% to 55% film savings over currently available competitive stretch wrapping systems.

R-Connect® Ready

Able to install R-Connect® remote monitoring software immediately.

With CUBE® Technology!

Our innovative CUBE® Technology offered on this machine combines the following four (4) key factors to successfully wrap loads & ensure that they reach your customer in “as-made” condition by maintaining proper wrapping standards.

- Multi-Level Variable Pre-Stretch ensures the best film economy & delivers 30-55% film savings.

- Multi-Level Variable Containment Force delivers optimal containment force at each level of the load.

- Pro-Active Corner Compensation enables you to wrap any load securely without corner damage or repetitive film breaks.

- Strategic Film Placement allows you to place film exactly where it has the most impact on load stability and containment.

AUTOMATIC LOAD HEIGHT SENSING AND FILM TAIL TREATMENT

Automatically senses top of load to provide your load with full film coverage. Cut, clamp, and wipe down unit secures the film tail at the end of the wrap cycle to the load to avoid loss of containment at the bottom of the load.